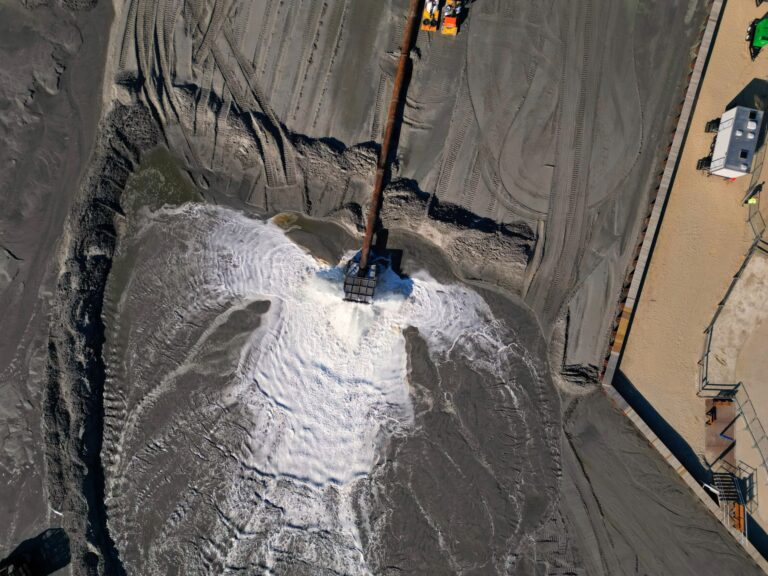

In any dredging operation, choosing the best dredge pump is critical to achieving efficient and productive results. Dredge pumps are the heart of the operation, responsible for moving large volumes of sediment, sand, and other materials from one location to another. Whether you are dredging in shallow waters or deep underwater, the dredging equipment you select can significantly impact the overall efficiency, cost-effectiveness, and longevity of your project. A well-chosen dredge pump reduces operational downtime, ensures smooth material handling, and increases the overall output of the operation.

In this article, we will explore the key considerations for selecting the best dredge pump, look at the various pump types, and guide on matching pump features to specific dredging tasks. Additionally, we will discuss maintenance tips and how to balance budget with performance when selecting a pump.

1. Key Considerations for Selecting an Optimal Dredge Pump

Project Requirements

Before selecting the best dredge pump, it is essential to understand the specifics of the project at hand. The scope and scale of your dredging operation will determine the size, type, and power of the pump needed. One of the first questions to ask is: What type of material will the pump be handling? Different pumps are designed to handle different types of material, such as fine sand, silt, or coarse gravel. For example, materials like sand or fine sediment may require a different pump compared to rocks or abrasive gravel, as the latter can wear down dredging equipment components faster.

Additionally, the depth and distance of the dredging operation must be factored in. A project that involves moving material over long distances or from deep underwater may require more power or a higher flow rate compared to shallow dredging operations. Choosing the optimal dredge pump for your specific requirements is crucial.

There are several types of dredge pumps available, and each has its pros and cons depending on the specific project requirements. The four main types are hydraulic, electric, submersible, and mechanical pumps.

- Hydraulic pumps are powerful and ideal for large-scale, heavy-duty dredging operations. They can handle a variety of materials and offer strong performance, but they tend to be more expensive and require specialized dredging equipment.

- Electric pumps are energy-efficient and best suited for smaller projects or operations where power efficiency is a priority. They are quieter but may lack the power required for larger tasks.

- Submersible pumps are designed to operate underwater and are ideal for projects that require dredging at greater depths. These pumps can handle significant volumes of water and sediment while reducing the need for auxiliary equipment.

- Mechanical pumps are typically simpler and used for smaller-scale dredging projects. While they are less expensive, they may not be suitable for highly abrasive materials or heavy-duty applications.

Choosing the right pump type depends on the scale, environment, and specific needs of the dredging project. The best dredge pump for your operation should match your specific requirements.

Flow Rate and Head Pressure

Flow rate and head pressure are two critical factors that directly impact the best dredge pump’s efficiency and performance. The flow rate refers to the volume of material the pump can move in a given period, while the head pressure measures the pump’s ability to overcome the resistance created by the distance and height of the material being transported.

For projects that require moving material over longer distances or against gravity, the best dredge pump with higher head pressure is necessary. On the other hand, for projects where large volumes of material need to be moved over shorter distances, a pump with a higher flow rate might be more suitable. Properly matching these factors to the project ensures smoother operations and minimizes the risk of pump failure.

2. Matching Pump Features to Specific Dredging Applications

Shallow vs. Deep Dredging

The depth of the dredging operation plays a significant role in selecting the best dredge pump. For shallow dredging, centrifugal dredge pumps are often preferred due to their ability to handle high volumes of material with lower head pressures. These pumps are effective and can be used in conjunction with other dredging equipment.

In contrast, submersible dredge pumps are better suited for deeper operations. These pumps can work directly underwater, eliminating the need for long intake pipes and providing more efficient material handling at greater depths.

Abrasive Material Handling

When dealing with abrasive materials like rocks, gravel, or coarse sand, it’s crucial to choose the best dredge pump with wear-resistant components. Using subpar equipment can lead to significant wear and tear, especially in harsh environments where abrasive materials are common. To minimize maintenance and downtime, selecting dredging equipment that features pumps made from hardened metals or specialized coatings is essential. An optimal dredge pump, designed specifically for handling abrasive materials, can significantly extend the lifespan of the equipment and ensure more efficient, reliable operations.

Environmental Impact

For projects in environmentally sensitive areas, choosing the best dredge pump designed to minimize environmental disruption is essential. Low-impact pumps, such as those with noise-reducing features or eco-friendly designs, are ideal for projects where the surrounding ecosystem needs to be protected. The best dredge pump, in these cases, helps reduce noise pollution and limits the disturbance to marine life or sedimentary environments, ensuring that the dredging operation has minimal ecological impact.

Selecting the optimal dredge pump for projects with environmental concerns is important to avoid negative ecological impacts.

3. Maintenance and Durability Tips

Routine Maintenance

No matter how advanced or powerful a dredge pump may be, regular maintenance of your dredging equipment is essential for ensuring its longevity and consistent performance. Routine inspections can help identify potential wear and tear before they lead to significant issues. Key components like seals, impellers, and bearings should be checked frequently to ensure they are functioning correctly and not showing signs of damage. By maintaining your dredging equipment properly, you can ensure that even the best dredge pump continues to operate efficiently and reliably over time.

Durable Components

Investing in the best dredge pump with corrosion-resistant and wear-resistant components can significantly extend its lifespan, especially for projects involving abrasive or corrosive materials. An optimal dredge pump made from high-quality, durable materials reduces the need for frequent part replacements, minimizing maintenance costs and operational downtime. When selecting dredging equipment, it’s essential to prioritize pumps designed to withstand harsh conditions, ensuring long-term reliability and efficiency in your operations.

A well-maintained dredging equipment setup that includes the best dredge pump will ensure optimal operation and prevent unnecessary interruptions.

4. Budget vs. Performance

When selecting a dredge pump, balancing budget considerations with performance needs is crucial. While premium, high-efficiency pumps come with a higher upfront cost, they often pay off in the long term through lower maintenance, reduced downtime, and improved energy efficiency. It’s important to evaluate whether investing in a more expensive optimal dredge pump could lead to cost savings and better performance over the lifespan of the project.

Conclusion

Choosing the best dredge pump for your operation involves a thorough assessment of the project requirements, including the type of material, the depth and distance of dredging, and the environmental conditions. Understanding the different pump types and matching their features to the needs of your project can optimize performance and reduce downtime.

Consulting with dredging experts or dredging equipment suppliers is a smart step to ensure you select the most efficient and cost-effective pump for your dredging operation. Whether you’re working in shallow waters or dealing with abrasive materials, choosing the optimal dredge pump can make all the difference in ensuring the best possible results for your project.