Dredging projects are a vital part of many large-scale construction operations, particularly those involving waterways, ports, and harbors. The efficiency of these projects heavily relies on connecting dredge pipelines properly. These pipelines are responsible for transporting dredged material such as sediment, sand, and debris from the dredging site to the disposal area. Without proper techniques for connecting dredge pipelines, there is a higher risk of leaks, downtime, and inefficiencies. This comprehensive guide to dredge pipelines will provide insights into construction pipeline connection techniques, tools for dredging, and best practices for ensuring reliable connections throughout the project.

1. Understanding the Basics of Dredge Pipelines

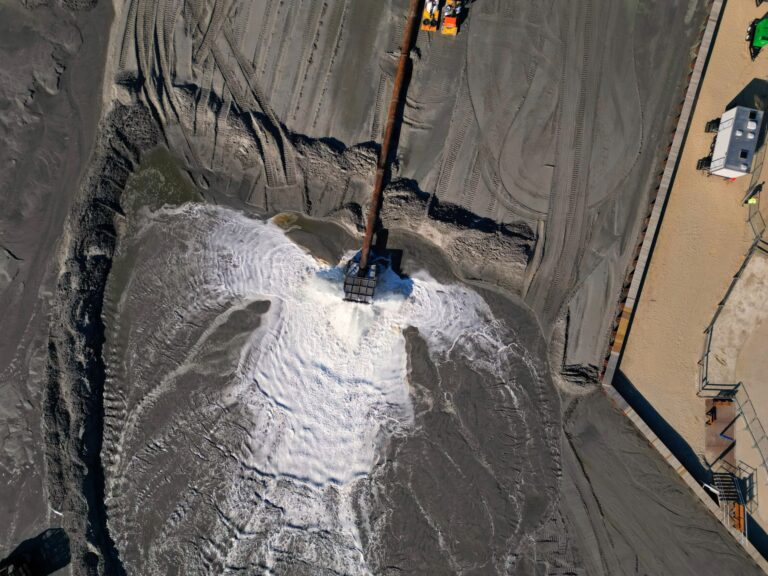

Before delving into the techniques for connecting dredge pipelines, it is essential to understand their role and structure. Dredge pipelines transport slurry—a mixture of water and solids—during dredging operations, moving it from the dredging site to its final disposal location. The effectiveness of these pipelines determines the overall efficiency of the operation, making their connection a critical step. This comprehensive guide to dredge pipelines will help you better understand the types and challenges involved in pipeline connections.

There are three main types of dredge pipelines:

- Floating pipelines: Used primarily on the water’s surface, these pipelines are supported by floaters to ensure they remain above water. Their flexibility makes them ideal for operations where the pipeline must adjust with the movement of the dredger.

- Submerged pipelines: These pipelines rest on the riverbed or seafloor and transport slurry beneath the water’s surface. Submerged pipelines are often used in deeper dredging projects, where protecting the pipeline from surface interference is necessary.

- Land-based pipelines: These pipelines carry the dredged material from water bodies to land-based storage or disposal areas. Typically constructed from steel or high-density polyethylene (HDPE), they are designed to withstand high pressure and large volumes of material.

One of the common challenges when connecting dredge pipelines is ensuring the pipeline remains securely fastened while accommodating the constant flow and pressure of the slurry. Floating pipelines are particularly vulnerable to shifts caused by waves and currents, making reliable connections crucial for maintaining operational integrity.

2. Construction Pipeline Connection Techniques

Construction pipeline connection techniques are key to ensuring efficient operations and preventing leaks. Connecting dredge pipelines requires precision and specific methods tailored to the material of the pipeline.

When connecting dredge pipelines, proper alignment is the first step. Any misalignment in the pipeline sections can cause leaks, reduce efficiency, and lead to mechanical damage. Below are the most common techniques used for different types of pipelines:

- Rubber hoses: These flexible pipelines are often used in areas where movement is frequent. Rubber hoses are connected using clamps, which ensure a secure seal while maintaining flexibility. This allows for pipeline movement without breaking the connection, which is particularly important for floating pipelines.

- Steel pipes: In many dredging projects, steel pipes are the go-to choice for land-based and submerged pipelines. These pipes are often connected using welding. Welding creates a seamless connection that can withstand the pressure of slurry transport, ensuring that the pipeline operates efficiently over long distances.

- HDPE pipes: Known for their durability and flexibility, HDPE pipes are often used in dredging operations. The most common method of connecting HDPE pipes is heat fusion, which involves heating the ends of the pipes and pressing them together to create a leak-free bond. This process ensures a robust and flexible connection that can handle the dynamic pressures of dredging operations.

Each of these construction pipeline connection techniques is crucial to maintaining the reliability of dredge pipelines. Proper alignment and secure connections prevent leaks and downtime, ensuring that the dredging operation runs smoothly.

3. Tools and Equipment for Dredging Pipeline Connections

The right tools and equipment are essential for connecting dredge pipelines effectively. These tools help ensure that the pipeline connections are strong, durable, and capable of withstanding the pressures of dredging operations. In this section of our comprehensive guide to dredge pipelines, we focus on the tools for dredging that make the connection process easier and more reliable.

- Couplers: These are used to join two sections of the pipeline securely. Couplers are available in different sizes and materials, making them versatile enough for various types of dredge pipelines. They provide a tight, secure fit and are easy to install, making them ideal for quick adjustments during dredging operations.

- Clamps: Clamps are commonly used to secure flexible hoses and smaller pipeline sections. These adjustable devices are crucial for keeping rubber hoses tightly connected to other sections of the pipeline, preventing leaks while allowing for the necessary flexibility.

- Flanges: Used primarily with steel and HDPE pipelines, flanges provide a solid and reliable connection. The flanges are welded or fused to the end of each pipeline section, and bolts are used to secure the connection. This type of connection is ideal for pipelines that experience high pressures, ensuring no leakage occurs.

In addition to these tools for dredging, specialized equipment such as pipe floaters and lifting mechanisms are often required when connecting dredge pipelines. Pipe floaters ensure that floating pipelines remain above the water while lifting mechanisms help position heavy pipeline sections for secure connections.

Safety is also a top priority when using tools for dredging. Proper handling of heavy machinery, securing tools to prevent accidents, and following safety guidelines are all critical to maintaining the safety and efficiency of the operation.

4. Best Practices for Connecting Dredge Pipelines

Best practices for connecting dredge pipelines go beyond using the right tools and techniques. These practices help ensure that the pipeline system remains efficient and durable throughout the dredging project.

- Pipeline integrity: One of the best practices is to regularly inspect the pipeline connections to ensure their integrity. Dredging operations place significant stress on pipelines, so frequent checks help identify wear or weaknesses that may need attention.

- Support systems: For floating pipelines, regularly check that the floaters are positioned correctly and the pipeline is not sagging or shifting. This will help prevent unnecessary stress on the connections, ensuring they remain strong and intact throughout the operation.

- Environmental considerations: Properly connecting dredge pipelines is also important for minimizing environmental impact. Care must be taken to avoid spills or leaks, which could harm the surrounding ecosystem. Using environmentally friendly materials and adhering to industry standards are essential steps to mitigate potential damage.

By following these best practices, dredging operations can minimize risks and ensure that their pipelines function optimally, reducing the chances of costly delays or failures.

Conclusion

Connecting dredge pipelines is an essential task in any dredging project, and ensuring that these connections are secure and reliable is key to maintaining operational efficiency. By understanding the different types of pipelines, applying the correct construction pipeline connection techniques, and utilizing the appropriate tools for dredging, construction teams can ensure the success of their operations. Regular maintenance, support systems, and environmental considerations further contribute to the longevity and reliability of the pipeline connections. Following these guidelines will ensure that connecting dredge pipelines is done efficiently, keeping dredging projects on schedule and under budget. The importance of connecting dredge pipelines cannot be overstated, as it is crucial to the success of the overall operation.