In the world of dredging, pipeline stability and safety are crucial to the success of any operation. Pipelines serve as the arteries through which slurry, sediment, and other materials are transported, often across long distances. Any disruption to the pipeline’s stability can cause costly delays, increase maintenance demands, and pose significant safety risks to the crew and environment. Ensuring the continuous and safe operation of pipelines is a top priority for dredging companies, and this is where dredge pipeline floats come into play.

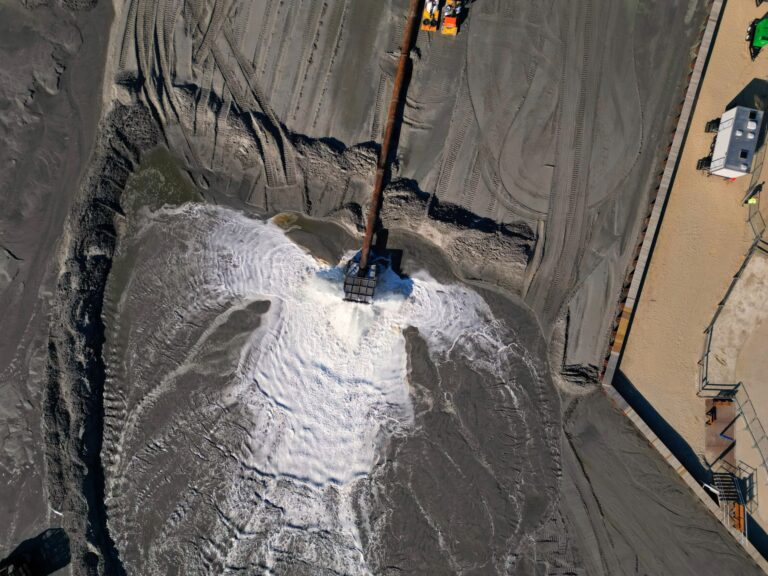

Dredge pipeline floats play a vital role in supporting pipelines during dredging operations, helping to keep them stable and secure. These buoyant devices ensure that pipelines are properly positioned, protected from environmental elements, and aligned to prevent damage. Using high-quality dredge pipeline floats can significantly enhance the efficiency and safety of pipeline operations, reducing the risk of failure and ensuring smooth, uninterrupted material flow.

In this article, we will discuss how high-quality dredging pipeline floats contribute to the efficiency and safety of pipeline operations, the different types of floats available, and why investing in durable, reliable floats is essential for long-term success.

Understanding Dredge Floats in Pipeline Operations

What Are Dredge Floats?

Dredge pipeline floats are buoyant devices that are attached to pipelines used in dredging operations. Their primary function is to keep the pipeline afloat, preventing it from sinking into the seabed or becoming damaged by abrasive surfaces, rocks, and other underwater obstacles. Dredge floats ensure that the pipeline remains buoyant, properly aligned, and in an optimal position for material transport. These floats are necessary for the pipeline to sink, misalign, or suffer damage, resulting in operational delays and increased maintenance costs.

Types of Dredge Floats

There are two main types of dredge floats used in the industry: foam-filled floats and inflatable floats.

- Foam-filled floats: These floats are known for their durability and consistency. Made from solid, puncture-resistant materials, foam-filled floats provide reliable buoyancy over long periods. They are ideal for large-scale projects where continuous support and stability are needed.

- Inflatable floats: These floats are lightweight and easy to transport, as they can be deflated when not in use. Inflatable dredge floats are often used in smaller-scale operations or in environments where flexibility and ease of handling are essential. While more durable than foam-filled options, inflatable floats provide sufficient buoyancy for shorter or less demanding dredging projects.

Key Role in Pipeline Safety

Dredge pipeline floats play a crucial role in maintaining pipeline safety by ensuring that the pipeline remains properly supported throughout the dredging operation. Without these floats, the pipeline would be exposed to environmental hazards, such as strong currents, sediment accumulation, or sharp objects on the seabed. This exposure could lead to damage, misalignment, or even complete failure of the pipeline. By providing buoyancy and stability, dredge floats protect the pipeline from these risks, allowing for continuous and efficient operations.

The Importance of High-Quality Dredge Pipeline Floats

Durability and Reliability

High-quality dredge pipeline floats are essential for ensuring long-term durability and reliability in dredging operations. Floats made from high-grade materials, such as polyethylene, offer superior resistance to damage caused by abrasion, UV rays, and saltwater corrosion. These materials ensure that the floats can withstand the harsh conditions of the marine environment, reducing the risk of failure and minimizing maintenance needs.

Reliable dredge floats are designed to last for extended periods, even under challenging conditions. Investing in durable floats not only protects the pipeline but also reduces the frequency of repairs and replacements, saving both time and money in the long run.

Resistance to Environmental Factors

Dredging operations often take place in environments where pipelines are exposed to extreme conditions, such as fluctuating temperatures, salt water, and debris. High-quality dredge pipeline floats provide a layer of protection against these environmental factors, preventing damage and wear over time. Floats made from premium materials resist degradation from prolonged exposure to UV rays and harsh chemicals, ensuring that the pipeline remains buoyant and intact throughout the operation.

By resisting environmental wear and tear, high-quality dredging pipeline floats help maintain pipeline efficiency and stability, contributing to safer and more reliable operations.

Long-Term Performance

One of the most significant advantages of using premium dredge pipeline floats is their ability to enhance the long-term performance of pipelines. High-quality floats reduce the need for frequent maintenance, repairs, and replacements, ensuring that the pipeline remains fully operational throughout the dredging project. Their durability also helps extend the overall lifespan of both the floats and the pipeline, leading to fewer disruptions and lower operational costs.

Investing in premium dredge pipeline floats means investing in the long-term success of your dredging operations, as they provide consistent support and protection over time.

Enhancing Efficiency with Dredge Pipeline Floats

Improving Pipeline Alignment

Proper pipeline alignment is critical to the success of any dredging operation. Misaligned pipelines can lead to disruptions in material flow, blockages, and increased pressure on certain sections of the pipeline. High-quality dredge pipeline floats play a key role in maintaining proper pipeline alignment, ensuring that the pipeline remains in its designated position throughout the operation. This stability helps reduce the risk of misalignment and the operational issues it can cause.

By keeping the pipeline properly aligned, reliable dredge pipeline floats ensure smooth and efficient transport of materials, preventing delays and costly repairs.

Ensuring Smooth Material Flow

The stability provided by dredge floats is essential for maintaining smooth material flow through the pipeline. Unstable pipelines can cause blockages, interruptions, and uneven material distribution, all of which can negatively impact the efficiency of the dredging operation. High-quality floats help keep the pipeline stable and free from obstruction, allowing for continuous and consistent material flow.

This improved material flow contributes to the operation’s overall efficiency, reducing the time needed to complete the project and ensuring that deadlines are met.

Minimizing Operational Downtime

One of the most significant benefits of using high-quality dredge pipeline floats is the reduction in operational downtime. Pipeline failures, misalignment, or damage can cause substantial delays, halting operations and increasing costs. By using durable, reliable dredging pipeline floats, companies can minimize the risk of pipeline failure and the resulting downtime. This ensures that operations run smoothly, with fewer interruptions and less need for emergency repairs.

Reducing operational downtime not only saves money but also improves overall project efficiency and helps maintain timelines.

Conclusion

High-quality dredge pipeline floats are essential for ensuring both the efficiency and safety of pipeline operations in dredging projects. By providing durability, resistance to environmental factors, and long-term reliability, these floats protect pipelines from damage and ensure smooth, uninterrupted material flow. Their role in maintaining proper pipeline alignment and minimizing operational downtime further enhances the overall success of dredging operations.

In summary, investing in premium dredge pipeline floats is a critical step for companies looking to enhance the safety and efficiency of their dredging operations. By prioritizing high-quality floats, companies can ensure the longevity and success of their projects, reduce maintenance costs, and avoid costly delays.