Small dredging equipment, a necessity for modern infrastructure, serves various industries, including mining, oil and gas, ports, municipal water management, and defense. These fields rely heavily on effective silt removal to keep streams passable, protect assets, and assure environmental compliance.

As global trade expands and inland waterway projects proliferate, demand for dredging appears to be increasing. At the same time, costs have escalated due to increased energy demands, complex permitting requirements, and specialized labor needs. Capital dredging projects, such as harbor deepening, are significantly more expensive than routine maintenance dredging, which leads to pressure on budgets and timelines.

Against this backdrop, organizations must carefully evaluate their choice of equipment. Large dredgers deliver scale and capacity, but small dredging equipment often provides a more efficient and cost-effective option for targeted work, with the added benefit of low cost for mobilization and operation. Understanding the trade-offs between large and small systems is crucial for maximizing return on investment (ROI), controlling expenses, and achieving operational efficiency. Selecting the right equipment for each project is essential, especially when considering small pond dredging or specialized gold dredging equipment, as they can deliver better outcomes than oversized alternatives.

Overview of Dredging Equipment Categories

Dredging equipment is broadly categorized by size, method, and application. Selecting the right option requires aligning project scope with both technical and financial considerations. Hydraulic dredgers, which utilize water jets and suction technology, represent a specific category designed for efficient sediment removal. Grab dredgers are another type of equipment used for excavation tasks, particularly in river and lake maintenance or environmental remediation. Specialized machinery, purpose-built for underwater excavation and sediment removal, is essential for effective dredging operations. Choosing the appropriate dredging method—such as suction, cutter suction, or jet suction—based on project requirements is crucial. Specialized dredging equipment further enhances efficiency, especially in challenging or aquatic environments.

Large Dredging Equipment

Large-scale systems are engineered for high-capacity operations:

- Cutter Suction Dredgers (CSDs): A cutter suction dredger is equipped with a rotating cutter head to break down compacted or rocky material before pumping it as a slurry. They are commonly used for land reclamation, channel deepening, and large-volume excavation.

- Trailing Suction Hopper Dredgers (TSHDs): Self-propelled vessels (and other marine vessel dredgers) designed to vacuum soft sediments while underway, storing them in hoppers for transport and disposal. They are highly effective for beach nourishment, port maintenance, and offshore projects.

While these systems deliver unmatched efficiency at scale, they require complex mobilization and higher operating costs, making them less suitable for smaller or short-term assignments.

Small Dredging Equipment

By contrast, small dredging equipment offers mobility, versatility, and lower capital investment. This category encompasses portable dredges, compact hydraulic systems, and units specifically designed for small pond dredging and mining operations. A small dredge is particularly suitable for niche or hard-to-access water bodies, offering flexibility and efficiency for specialized projects. Examples include:

- Portable Dredges: Lightweight and easy to transport, these units are ideal for inland waterways, canals, and confined work sites.

- Small Pond Dredging Units: Specifically designed for ponds, lakes, and reservoirs, these systems remove accumulated sediment efficiently without the scale of large vessels.

- Mini Dredge: Compact and portable, mini dredges (also referred to as a small sand dredge) are designed for small-scale or hard-to-reach waterway projects, offering efficiency and versatility.

- Dredge Sled: A remote-controlled, automated mini dredge system for removing sand, silt, and debris from ponds, lagoons, and waterways.

- Gold Dredging Equipment: Specialized solutions for extracting fine sediment and valuable minerals in shallow rivers and streams. These systems demonstrate how small-scale dredging equipment can generate economic value while remaining practical for localized use

For municipal buyers, contractors, and industrial operators, small dredging equipment provides advantages in deployment speed, reduced energy use, and lower overall costs. Whether managing tailings ponds, restoring reservoirs, or performing small pond dredging, these systems align closely with the needs of targeted, budget-sensitive projects.

Mechanical, Hydraulic, and Specialty Approaches

Dredging methods can be classified by how material is removed:

- Mechanical Dredging: Uses grabs, buckets, or backhoes to physically excavate sediment, offering precision in harbors or restricted areas.

- Hydraulic Dredging: Hydraulic dredgers utilize pumps to transport material as a slurry, allowing for continuous operations across rivers, lakes, or coastal zones. These systems are commonly used to remove sediment from water bodies. Hydraulic dredgers extract material from underwater environments using suction technology.

- Specialty Dredging: Focused on environmental protection or contaminated sites, using low-turbidity and controlled techniques.

Both large and small dredging equipment can fit into these categories. However, choosing between large vessels and more agile systems, such as gold dredging equipment or small pond dredging units, depends on balancing efficiency, site conditions, and budget priorities.

What is Dredging?

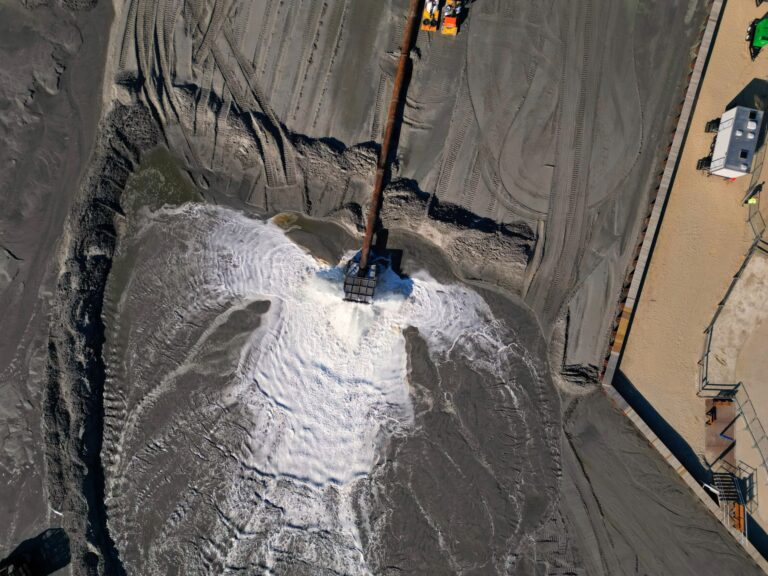

Dredging is the process of excavating and removing sediment, silt, or debris from water bodies such as rivers, lakes, harbors, and coastal areas using specialized dredging equipment. This essential operation helps maintain navigable waterways, ensuring that shipping channels, ports, and marinas remain accessible for marine traffic. Dredging operations utilize a range of machinery, including cutter suction dredgers, hydraulic dredgers, and suction dredgers, each designed to extract material from the bottom of water bodies efficiently.

The process typically involves loosening material from the seabed or riverbed—often with a rotating cutter head or suction tube—before transporting the dredged material through pipelines or hoppers to designated disposal or reclamation sites. By removing sediment and debris, dredging supports flood prevention, infrastructure development, and environmental restoration. Whether the goal is to deepen a channel, extract material for land reclamation, or remove sediment buildup, the right combination of dredging method and equipment is crucial for project success.

Cost Drivers in Dredging Operations

A combination of capital expenses, operating costs, and regulatory obligations influences the financial structure of dredging projects. Understanding specific dredging needs and the range of dredging applications is essential for accurate cost estimation, as different projects require tailored equipment and approaches. Additionally, environmental regulations can significantly impact project costs and influence the selection of dredging equipment to ensure compliance. These factors can vary substantially depending on whether an organization invests in large vessels or opts for more agile solutions, such as dredging equipment.

Capital vs. Operating Costs

Large dredgers require significant upfront investment, often justified only for long-term or repeated use in major infrastructure projects. In contrast, dredging equipment reduces capital exposure, making it an attractive option for municipalities and contractors managing shorter project lifecycles. While operating costs exist in both categories, portable units designed for small pond dredging or targeted cleanup work typically consume less fuel and require fewer operators.

Equipment Purchase or Rental Pricing

Procurement teams must weigh the cost of outright purchase versus rental. Large systems demand substantial financing commitments and longer lead times for mobilization. Small dredging equipment, however, is frequently available through flexible rental models, allowing contractors to deploy units for niche assignments such as environmental cleanup or gold dredging operations. DAE Pumps is a leading provider of portable mini dredges available for rental.

Logistics, Labor, and Energy

The mobilization of large dredgers involves tugboats, specialized crews, and extensive fuel consumption. Smaller systems mitigate these challenges by reducing transport complexity and minimizing crew requirements. For projects such as small pond dredging, the ability to deploy equipment quickly without extensive logistics can lead to measurable cost savings. Additionally, efficient pumping operations in small dredging equipment help reduce both labor and energy requirements, further enhancing overall project efficiency.

Permitting and Compliance

Regulatory requirements, including environmental impact assessments and ongoing monitoring, contribute significantly to overall project costs. Environmental considerations are crucial for minimizing ecological disruption, maintaining water quality, and ensuring compliance with regulations through sustainable practices and mitigation measures. Although these apply to both large and small operations, the footprint of dredging equipment can reduce the scale of permitting obligations. In sensitive areas, especially when using gold dredging equipment, lower turbidity and smaller work zones can simplify compliance pathways.

Site-Specific Variables

Soil type, contamination levels, and access constraints significantly impact the overall cost. The characteristics of different water bodies, such as lakes, rivers, and canals, also influence the selection of dredging equipment. Large dredgers excel in open-water environments with massive sediment volumes, but confined areas such as reservoirs, canals, or municipal ponds favor small dredging equipment. Maintaining navigable waterways is essential for transportation and ecological health, and small dredging equipment plays a crucial role in waterway maintenance for confined or municipal areas. The adaptability of compact units makes them particularly suitable for precision work in small pond dredging projects where large systems are not economically viable.

Large Dredging Equipment: Efficiency and Limitations

Large dredging equipment is engineered for scale, designed to remove millions of cubic meters of material in offshore and coastal projects. Its efficiency is unmatched in capital-intensive undertakings, but these advantages come with significant financial and operational trade-offs.

By understanding the specific requirements of each project, decision-makers can identify where large vessels justify their cost and where more adaptable solutions, such as small dredging equipment, offer greater efficiency. Compared to other dredges, large dredging equipment may face limitations in accessing confined or sensitive areas, can have a greater environmental impact, and may not be as suitable for projects requiring minimal shoreline disturbance or specialized access.

Strengths of Large Equipment

- High-Volume Capacity: Cutter suction dredgers and trailing suction hopper dredgers move massive sediment volumes efficiently, often handling thousands of cubic yards of material per hour, supporting harbor deepening, coastal defense, and land reclamation.

- Suited for Long-Distance Transport: Large systems are capable of moving dredged material over extended distances, which is critical for offshore disposal or beach nourishment.

- Scalable Operations: With greater pumping power and vessel storage, these machines can operate continuously for extended periods without frequent downtime.

Limitations of Large Equipment

- High Upfront and Operating Costs: Acquisition, crew training, and ongoing fuel requirements result in a higher cost of ownership compared to small dredging equipment.

- Mobilization and Demobilization Challenges: Large dredgers require extensive preparation, tug support, and infrastructure to transport and deploy, compared to portable solutions like small pond dredging equipment.

- Limited Suitability for Smaller Projects: For municipal canal maintenance, localized environmental remediation, or precision applications like gold dredging equipment, large dredgers are rarely economical. Small dredging equipment delivers better ROI when project scale is limited, timelines are short, or access is constrained.

By weighing these strengths and limitations, decision-makers can identify where large vessels justify their cost and where more adaptable solutions, such as small dredging equipment, offer greater efficiency.

Small Dredging Equipment: Efficiency and Limitations

Small dredging equipment is a practical and efficient choice for many projects, particularly those with limited scope and budget. Its versatility makes it ideal for municipal projects, inland waterways, and industrial areas that do not require a big dredger capacity. Efficient sediment removal is a key advantage of small dredging equipment, supporting environmentally sustainable and cost-effective operations. Dredging depth is an important factor that influences equipment selection and project complexity, as deeper projects may require specialized machinery. Additionally, small dredging equipment is designed to pass solids of various sizes, making it suitable for a wide range of sediment removal tasks.

Strengths of Small Equipment

- Cost-Effective for Confined Sites: The lower purchase or rental cost of small dredging equipment allows organizations to maintain efficiency while keeping expenditures predictable. These systems are particularly valuable in rivers, lakes, and restricted-access waterways.

- Portable and Easy Deployment: Unlike large dredgers that require complex mobilization, compact units can be deployed quickly with minimal support, reducing downtime and accelerating project schedules. The use of a submersible pump increases durability and efficiency, especially in confined environments.

- Ideal for Targeted Applications: Small pond dredging projects benefit from equipment that can operate in tight spaces without overextending budgets. Likewise, gold dredging equipment is designed for precise recovery in shallow rivers and streams, showing how small systems excel in specialized environments. The advantages of a direct drive cutter head include high-torque operation and ease of maintenance, making these systems robust and reliable. Advanced cutter heads also play a crucial role in improving equipment performance and productivity.

- Reduced Fuel and Energy Consumption: Smaller-scale dredgers consume less energy, making them more sustainable for limited projects and minimizing long-term operational costs.

Limitations of Small Equipment

- Lower Throughput: The capacity of small dredging equipment is naturally less than that of larger vessels, which limits its effectiveness on projects requiring the removal of millions of cubic meters of sediment. As a result, small dredging equipment is not intended for large dredging operations due to its scale limitations.

- Less Suited for Major Infrastructure: Applications such as harbor deepening or offshore land reclamation are beyond the efficiency range of small dredging equipment, making them unsuitable for large-scale coastal or industrial undertakings.

By weighing these strengths and constraints, decision-makers can better align small dredging equipment with projects where mobility, cost efficiency, and flexibility outweigh the need for high-volume capacity.

Side-by-Side Cost and Efficiency Comparison

To better illustrate the differences between large and small systems, the following table highlights the most important cost and efficiency factors. This direct comparison highlights the competitive advantages of dredging equipment, particularly in localized operations, small pond dredging, and gold dredging projects. Specialized equipment such as a dredge pump and pontoon dredge are commonly used for small-scale projects due to their portability and adaptability. A pontoon dredge pump provides a floating, mobile solution ideal for shallow water applications. The discharge pipeline is a critical component, efficiently transporting sediment from the excavation site to disposal or processing locations.

| Factor | Large Dredging Equipment | Small Dredging Equipment |

| Capital Cost | High | Low–Moderate |

| Mobilization | Complex, expensive | Simple, fast |

| Throughput | Very high | Moderate–low |

| Site Suitability | Large-scale, offshore ports | Inland, ponds, small pond dredging, mining tailings, gold dredging equipment |

| Energy Use | High | Lower |

| ROI Profile | Long-term, capital-intensive | Short-term, flexible, project-based |

This comparison emphasizes how small dredging equipment reduces capital exposure, enables faster deployment, and optimizes ROI for targeted work. For municipal managers, contractors, and mining operators, compact systems offer clear value when dealing with confined environments or specialized needs, such as small pond dredging or recovering gold dredging equipment.

Environmental Impact of Dredging

The environmental impact of dredging is a critical consideration for any dredging project. Dredging operations can disturb aquatic habitats, resuspend sediments, and potentially release contaminants into the water column. These effects can disrupt local ecosystems and impact water quality if not properly managed. However, advancements in specialized dredging equipment—such as mini dredges, eddy pumps, and other efficient sediment removal systems—have made it possible to minimize these impacts.

Modern dredging projects often employ equipment designed for precision and low turbidity, such as the DAE Pumps Silt-Bot Mini Dredge, which allows for targeted sediment removal with minimal disturbance to surrounding habitats. Environmental considerations, including the careful removal of contaminated sediments and the protection of sensitive aquatic areas, are now standard practice in responsible dredging operations. By selecting the right dredging method and equipment, and by implementing best management practices, project teams can achieve efficient sediment removal while safeguarding the environment.

Matching Equipment to Real-World Applications

The choice between large and small dredging systems is determined by project scope, geography, and financial objectives. Each category has distinct use cases where it delivers maximum efficiency. Small dredging equipment is commonly used for removing sand, removing sediment, and removing contaminated sediments from ponds, lagoons, and other aquatic environments. These systems can efficiently pump sand from underwater or contained areas, making them ideal for sediment removal and pond cleanup projects. Taian Ocean Pump is a notable provider of small sand dredgers designed for shallow water applications.

Large Dredging Equipment

- Port Maintenance and Expansion: Cutter suction dredgers and trailing suction hopper dredgers are best suited for deepening harbors, expanding port infrastructure, and maintaining busy shipping lanes.

- Coastal Defense Projects: Large dredgers support beach nourishment and shoreline protection by moving massive volumes of sand and sediment.

- Offshore Oil & Gas Operations: High-capacity equipment is necessary to maintain offshore terminals and subsea infrastructure, where precision and throughput must align with the demands of large-scale energy production.

Small Dredging Equipment

- Mining Tailings Ponds: Small dredging equipment excels in confined industrial sites where rapid mobilization and low operating costs are essential. Mini dredge systems are often used for efficient sediment removal in these environments.

- Small Pond Dredging for Municipalities: Parks, reservoirs, and stormwater retention ponds often require sediment removal on a smaller scale, making small pond dredging equipment the most cost-effective option. Specialized dredging equipment can be tailored to address unique project requirements in these municipal settings.

- Gold Dredging in Rivers and Shallow Areas: Specialized gold dredging equipment provides efficient recovery in waterways where larger dredgers cannot operate economically. Using an eddy pump offers significant advantages for handling heavy-duty sediment and debris removal in these shallow or hard-to-reach areas.

Environmental Cleanup Projects: Precision removal of contaminated sediments is often best achieved with small dredging equipment, which minimizes turbidity and environmental impact.

ROI Considerations for Buyers and Contractors

Return on investment is a critical factor for procurement heads, engineering managers, and project contractors when evaluating dredging solutions. The diversity of dredging applications—such as sediment removal, shoreline restoration, habitat enhancement, and waterway maintenance—directly influences ROI calculations, as each application presents unique operational demands and benefits.

- Total Cost of Ownership (TCO): Large dredgers involve significant capital costs, but they may justify the expense in long-term, high-volume projects. In contrast, small dredging equipment reduces upfront investment and lowers energy consumption, making it ideal for shorter-duration work such as small pond dredging or targeted industrial maintenance.

- Efficiency Gains vs. Operational Risk: Large equipment offers unmatched throughput but exposes buyers to higher financial risk if project volumes are overestimated. Smaller systems provide flexibility and reduce exposure by aligning costs with actual project size.

- Rental vs. Purchase Scenarios: Rental models are increasingly common, particularly for small dredging equipment, which can be deployed for temporary needs, such as seasonal dredging or niche projects, like the recovery of gold dredging equipment. Large vessels, on the other hand, are typically purchased or leased for long-term use due to their scale and the requirements for mobilization.

- Case-Specific ROI: Many municipalities, mining companies, and contractors find that small dredging equipment outperforms larger alternatives when the scope is localized, timelines are tight, or budgets are limited. In these scenarios, savings on mobilization and fuel often outweigh the reduced throughput, resulting in stronger ROI.

Strategic Guidance and Project Support

Dredging projects are big investments, requiring a thorough cost-versus-efficiency analysis. Both large and small dredging systems are useful, but selecting the right one will determine whether a project stays on track, meets regulatory standards, and yields a high return on investment.

Pump and Dredge Direct is a trusted partner for decision-makers across mining, oil & gas, municipal, and heavy industry sectors. We supply both large and small dredging equipment, along with expert guidance to match the right solution to your project needs. For challenging or unique project requirements, we also offer specialized dredging equipment designed to maximize efficiency and performance.

Connect with us now to discuss your upcoming dredging requirements and receive a custom recommendation that ensures cost efficiency, performance, and long-term project success.

Summary of Key Points

In summary, dredging is a vital process for maintaining navigable waterways and supporting a wide range of marine and infrastructure projects. The use of specialized dredging equipment—such as cutter suction dredgers, pontoon dredge pumps, and mini dredges—enables efficient sediment removal tailored to the unique needs of each project. Dredging companies like Taian Ocean Pump provide essential services and equipment for applications ranging from lagoon dredging to environmental cleanup.

Environmental considerations are paramount, and the adoption of advanced dredging technology, including DAE Pumps Silt-Bot Mini Dredge and other specialized machinery, helps minimize ecological impact. Key components such as dredge pumps, cutter heads, and booster pumps must be carefully selected and maintained to ensure project efficiency and effectiveness. Ultimately, successful dredging operations depend on matching the right equipment and method to the specific dredging needs, whether that involves removing sand, managing sediment buildup, or addressing contaminated sites. With careful planning and a commitment to sustainability, dredging projects can achieve both operational and environmental goals.