Marine dredging contractors play a crucial role in coastal development, port maintenance, and land reclamation by removing sediment, deepening waterways, and constructing artificial landmasses. Their work is essential for ensuring safe navigation in busy harbors, preventing coastal erosion, and supporting large-scale infrastructure projects. However, marine dredging in harsh ocean environments presents unique challenges that can complicate operations and increase costs.

Unlike inland or lake dredging, marine projects must contend with unpredictable weather patterns, strong ocean currents, and varying tidal conditions. Deepwater dredging requires specialized equipment designed to withstand extreme conditions while maintaining efficiency. Additionally, saltwater exposure accelerates equipment corrosion, making maintenance a critical factor in operational success.

Marine dredging contractors must implement advanced technologies, precise navigation systems, and rigorous maintenance schedules to ensure sustainable and effective dredging. Environmental regulations add another layer of complexity, requiring compliance with strict guidelines to protect marine ecosystems.

This blog explores the key challenges faced by marine dredging contractors and the strategies they use to overcome them. By addressing these obstacles with innovative solutions, dredging operations can continue to support coastal and inland waterway development while minimizing environmental impact. Understanding these challenges is essential for ensuring the long-term success of ocean and lake dredging projects.

Unpredictable and Extreme Weather Conditions

One of the biggest challenges marine dredging contractors face is the impact of unpredictable and extreme weather conditions. Unlike inland projects, which operate in more controlled environments, marine dredging operations must contend with storms, high winds, and rough seas. These harsh conditions can halt operations, damage equipment, and create dangerous working environments for crews.

Severe storms, hurricanes, and sudden weather shifts can disrupt dredging schedules, leading to extended downtime and increased operational costs. High winds can make it difficult to maintain dredger positioning, while strong ocean currents can affect sediment transport, making dredging less efficient. Rough seas also pose safety risks, limiting crew mobility and making it difficult to conduct maintenance on dredging vessels. For marine dredging contractors working on long-term projects, unexpected weather delays can result in financial losses and project setbacks.

To mitigate these risks, contractors rely on advanced weather prediction systems and real-time monitoring technologies. Satellite data, meteorological forecasting tools, and oceanographic sensors help predict adverse conditions, allowing crews to plan accordingly. By monitoring wind patterns, wave heights, and tidal movements, dredging teams can adjust operations to ensure safety and efficiency.

Additionally, adopting flexible scheduling and contingency plans helps reduce the impact of weather disruptions. Having backup equipment, emergency response protocols, and alternative dredging strategies ensures that operations can resume quickly after severe weather events.

While marine dredging is more affected by extreme weather, lake dredging also faces similar challenges, particularly during heavy rainfall, flooding, or freezing conditions. Proper planning and real-time weather analysis are essential for both marine dredging contractors and those involved in lake dredging to maintain efficiency and project continuity in changing weather conditions.

Strong Currents and Tidal Variations

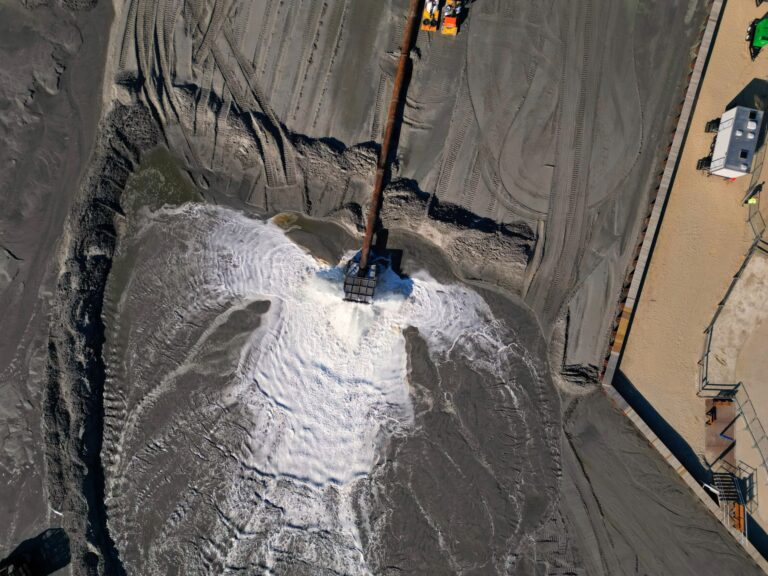

Marine dredging contractors frequently work in areas with strong ocean currents and shifting tides. These natural forces can significantly impact dredging precision, making it difficult to maintain control over equipment and ensure accurate sediment removal. Unlike inland operations such as lake dredging, which typically occur in more stable water conditions, marine dredging projects must account for constant changes in water movement that can shift dredged material and reduce efficiency.

One of the biggest concerns for marine dredging contractors is the effect of water movement on sediment transport. Strong currents can disperse dredged material over a wider area than intended, requiring additional efforts to relocate and contain the sediment. Tidal variations can also affect dredging depth, with fluctuating water levels making it challenging to maintain a consistent excavation. These factors not only slow down operations but also increase fuel consumption and equipment wear, leading to higher operational costs.

To counteract these challenges, advanced GPS-guided positioning systems and real-time monitoring technologies are used to improve dredging accuracy. GPS tracking allows operators to maintain precise positioning of dredgers, even in areas with high water movement. Real-time monitoring systems track current speeds, wave heights, and sediment displacement, enabling crews to adjust operations in response to changing conditions.

Additionally, automated dredging systems can help stabilize equipment in turbulent waters. Some modern dredgers are equipped with dynamic positioning technology, which automatically adjusts vessel positioning based on tidal and current data. By using these innovations, marine dredging contractors can significantly improve efficiency and reduce sediment loss.

While strong currents are primarily a concern in coastal and offshore projects, lake dredging can also be affected by water movement, particularly in large lakes with significant wind-driven currents. Adapting to these conditions is crucial for maintaining dredging precision and achieving project success.

Equipment Wear and Corrosion in Saltwater Environments

Marine dredging contractors face significant challenges due to the harsh effects of saltwater exposure on dredging equipment. Prolonged operation in ocean environments accelerates corrosion, weakening structural components and reducing the lifespan of critical machinery. Unlike freshwater operations such as lake dredging, marine projects must combat constant salt exposure, which leads to rust formation, metal degradation, and increased maintenance costs.

Saltwater is highly corrosive, attacking metal surfaces, pipelines, and hydraulic systems used in dredging equipment. This is particularly concerning for marine dredging contractors, as prolonged exposure can cause structural failures if preventive measures are not taken. Additionally, the combination of saltwater and abrasive sediments further accelerates wear on pumps, cutter heads, and dredging pipelines, leading to increased downtime and costly repairs.

The impact of abrasive sediments also poses a major challenge. Sand, gravel, and rock particles continuously erode key components such as pumps and cutter heads, reducing efficiency and requiring frequent replacements. Marine dredging contractors must ensure that their equipment is made from durable, wear-resistant materials that can withstand harsh operating conditions.

Proper maintenance practices and material selection are essential to mitigating these issues. Regular freshwater rinsing after dredging operations helps remove salt deposits and slow down corrosion. Protective coatings, such as marine-grade epoxy and anti-corrosion paints, can provide additional defense against rust. For high-wear areas, specialized materials like stainless steel or corrosion-resistant alloys improve durability.

While not exposed to saltwater, lake dredging operations can still experience equipment wear due to sediment abrasiveness. However, by adopting similar maintenance techniques, marine and lake dredging projects can enhance equipment longevity, reduce operational costs, and ensure consistent performance in challenging dredging environments.

Environmental and Regulatory Challenges

Marine dredging contractors must navigate strict environmental regulations designed to protect marine ecosystems, prevent excessive sediment displacement, and minimize water pollution. Governments and environmental agencies closely monitor dredging activities to ensure compliance with sustainability standards. These regulations often require contractors to implement strategies that limit environmental impact while maintaining operational efficiency.

One of the primary environmental challenges in marine dredging is sediment displacement. Dredging operations can stir up sediments, leading to increased turbidity, which reduces water quality and affects marine life. Suspended particles can smother coral reefs, disrupt fish habitats, and impact seagrass beds. Unlike lake dredging, where containment areas can often be used to control sediment spread, marine dredging projects operate in open-water environments, making turbidity management more difficult.

To address these concerns, marine dredging contractors must adopt eco-friendly dredging techniques and mitigation measures. One effective approach is using silt curtains, which act as barriers to prevent sediment from spreading beyond the dredging area. Additionally, employing precise dredging methods, such as GPS-guided equipment, helps minimize unnecessary sediment disruption.

Environmental impact assessments are also critical to regulatory compliance. Before starting a project, marine dredging contractors must conduct thorough evaluations to assess potential risks and develop mitigation plans. These assessments often include monitoring water quality, evaluating the impact on marine life, and implementing habitat restoration efforts.

Lake dredging projects, though operating in freshwater environments, also require careful planning to protect local ecosystems. Regulations may require sediment testing, controlled disposal of dredged material, and habitat restoration programs. By prioritizing compliance with environmental standards, marine dredging contractors can ensure sustainable operations while balancing economic and ecological responsibilities in both marine and lake dredging projects.

Navigational and Safety Risks

Marine dredging contractors operate in some of the most challenging environments, often working in busy shipping lanes, near offshore structures, and in deepwater conditions. These high-risk areas pose significant navigational and safety hazards, requiring careful planning and strict adherence to safety protocols to protect workers and ensure smooth operations.

One of the biggest challenges for marine dredging contractors is coordinating dredging activities in areas with heavy vessel traffic. Ports, harbors, and coastal waterways often have continuous maritime movement, making it essential to avoid collisions and disruptions. Miscommunication or equipment failure in these high-traffic zones can lead to accidents, property damage, and even legal consequences. Implementing advanced navigation systems, GPS tracking, and real-time communication with port authorities helps reduce these risks.

Deepwater dredging presents additional safety concerns. Harsh ocean conditions, unpredictable weather, and strong currents can make operations more dangerous. Crew members working in such conditions risk slips falls, and equipment-related injuries. Unlike lake dredging, which occurs in more controlled environments, offshore dredging requires specialized safety measures such as emergency response plans, life-saving equipment, and continuous weather monitoring.

Marine dredging contractors must enforce strict safety protocols to minimize accidents. These protocols include regular safety training, ensuring all crew members wear protective gear, and having emergency evacuation procedures in place. Additionally, automated monitoring systems can help detect potential hazards, such as equipment malfunctions or unstable operating conditions.

Even in inland water bodies, lake dredging projects require careful navigation and safety measures, particularly when working near dams, bridges, or recreational areas. By prioritizing worker safety and operational efficiency, marine dredging contractors can significantly reduce risks and ensure successful dredging projects in both marine and lake environments.

Logistical and Operational Challenges

Marine dredging contractors face significant logistical and operational challenges when mobilizing and deploying dredging vessels, particularly in remote or deepwater locations. Unlike inland projects, such as lake dredging, marine operations often require transporting large equipment over long distances, which increases costs and complicates project planning. Ensuring that all necessary machinery, spare parts, and supplies reach the site on time is critical to avoiding delays.

Fuel supply is another major concern for marine dredging contractors, especially in offshore locations where refueling options are limited. Dredging vessels consume substantial amounts of fuel, and maintaining an efficient fuel supply chain is essential to keeping operations running smoothly. Additionally, regular equipment maintenance must be planned carefully, as breakdowns in remote areas can result in extended downtime and high repair costs.

Workforce management also presents logistical challenges. Dredging crews often work on rotational schedules in demanding conditions, requiring proper accommodations, transportation, and safety measures. Unlike lake dredging projects, which can typically be managed with smaller crews, offshore dredging operations need larger teams and highly skilled personnel trained to handle complex dredging technologies.

To address these challenges, marine dredging contractors are increasingly turning to innovations in remote dredging operations and unmanned dredging technology. Autonomous dredgers, remotely operated equipment, and AI-driven monitoring systems reduce the need for on-site personnel and improve efficiency. These technologies help optimize dredging precision while minimizing risks associated with working in hazardous environments.

By leveraging these advancements, marine dredging contractors can improve operational efficiency, reduce costs, and enhance safety, making even the most challenging dredging projects more manageable. As technology continues to evolve, increased automation and smarter dredging solutions will benefit marine and lake dredging operations.

Conclusion

Marine dredging contractors face a wide range of challenges when operating in harsh ocean environments. From unpredictable weather and strong currents to equipment wear, environmental regulations, and safety risks, these obstacles require strategic planning and advanced technology to overcome. Unlike inland projects such as lake dredging, marine dredging presents unique difficulties that demand specialized equipment and expertise.

Innovation is key to improving efficiency and sustainability in dredging operations. By leveraging automation, GPS-guided dredging systems, and remote monitoring technologies, marine dredging contractors can enhance precision, reduce operational risks, and minimize environmental impact. Strict regulatory compliance and proactive maintenance strategies are also essential to ensuring long-term success.

Looking ahead, advancements in unmanned dredging vessels, AI-driven monitoring, and improved fuel efficiency will continue to shape the future of both marine and lake dredging. By adopting these emerging technologies, marine dredging contractors can navigate complex challenges while maintaining productivity, safety, and environmental responsibility in their operations.