Maintaining your pump and dredge equipment is essential to ensuring its longevity and optimal performance. Regular pump maintenance not only extends the life of your machinery but also helps prevent costly breakdowns and inefficiencies that can disrupt operations. In this article, we’ll explore practical tips and strategies for keeping your pump and dredge equipment in top condition through effective pump maintenance and dredge equipment maintenance practices.

Understanding the Basics of Pump and Dredge Equipment Maintenance

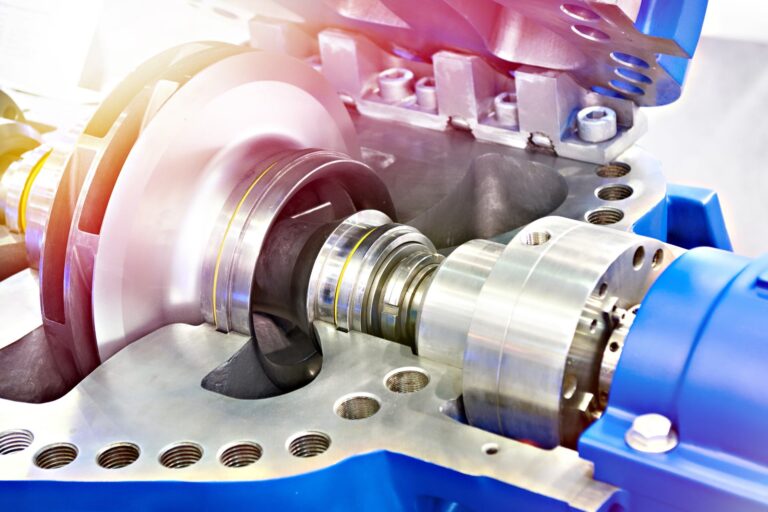

Pump maintenance involves a series of routine checks and procedures designed to keep your equipment running smoothly. This includes everything from daily inspections to seasonal preparations. Regular maintenance is crucial for preventing issues such as leaks, wear and tear, and mechanical failures, all of which can lead to downtime and expensive repairs. Effective dredge equipment maintenance plays a similar role in ensuring that dredging operations continue without interruption. Proper dredge machinery maintenance ensures that all components of the dredge equipment are functioning optimally, reducing the risk of unexpected failures.

The benefits of regular maintenance are clear: it helps extend the lifespan of your equipment, prevents unexpected breakdowns, and ensures that your pump and dredge equipment operates at peak efficiency. By taking a proactive approach, you can avoid the headaches and costs associated with reactive repairs, especially when it comes to dredge equipment troubleshooting.

Daily Maintenance Tips

Daily Visual Inspections: One of the simplest yet most effective pump maintenance practices is performing daily visual inspections. Take a few minutes each day to check for any obvious signs of wear or damage, such as leaks, cracks, or loose components. Pay special attention to hoses, seals, and gaskets, as these are common points of failure in both pump and dredge equipment. Regular inspections are a key part of dredge equipment maintenance.

Lubrication: Proper lubrication is essential for the smooth operation of moving parts. Ensure that all relevant components are adequately lubricated, using the appropriate type of lubricant recommended by the manufacturer. This helps reduce friction and wear, preventing premature failure of critical parts and ensuring effective dredge machinery maintenance. Regular lubrication is also a vital aspect of maintenance that contributes to the overall efficiency of your equipment.

Cleaning Routine: Keeping your equipment clean is vital for its longevity. Dirt, debris, and buildup can cause significant damage over time. Make it a habit to clean your pump and dredge equipment regularly, focusing on areas prone to accumulation. This not only prevents damage but also makes it easier to spot potential issues during inspections, contributing to more effective dredge equipment troubleshooting. A consistent cleaning routine is a key component of maintenance that should not be overlooked.

Weekly Maintenance Tips

Checking Fluid Levels: Fluid levels, such as oil and hydraulic fluids, play a crucial role in the operation of your equipment. Check these levels weekly and top them off as necessary. Low fluid levels can lead to overheating, reduced efficiency, and even catastrophic failures if left unaddressed. Regularly checking fluid levels is a fundamental aspect of both pump and dredge equipment maintenance.

Inspecting Mechanical Seals: Mechanical seals are vital in preventing leaks within your pump system. Regularly inspect these seals for signs of wear or damage, such as cracks or excessive wear. If you notice any issues, replace the seals promptly to avoid leaks and further damage during dredge equipment maintenance. Ensuring the integrity of seals is also a critical element of ongoing maintenance.

Monitoring Pump Performance: Keeping an eye on your pump’s performance is essential for early detection of potential problems. Pay attention to any changes in noise, vibration, or efficiency. Tools like pressure gauges and flow meters can help you monitor performance and catch issues before they escalate, which is crucial for effective dredge equipment troubleshooting. Regular monitoring is a proactive pump maintenance strategy that can prevent major issues.

Monthly Maintenance Tips

Detailed Equipment Inspection: Conduct a more thorough inspection of your entire system once a month. This includes checking key components like impellers, bearings, and couplings for wear and damage. A detailed inspection allows you to identify issues that may not be visible during daily or weekly checks. Regular monthly inspections are a cornerstone of comprehensive dredge machinery and pump maintenance.

Testing System Pressure: Maintaining the correct system pressure is critical for optimal performance. Test the pressure regularly and adjust it as needed. Too much pressure can cause excessive wear, while too little can lead to inefficiency and potential damage to the system, emphasizing the importance of regular pump maintenance and dredge equipment maintenance.

Calibration of Controls: Accurate control systems and sensors are essential for the safe and efficient operation of your equipment. Monthly calibration ensures that these systems are functioning correctly, helping to prevent overloading or underperforming components and aiding in effective dredge machinery maintenance. Calibration is also a vital part of thorough pump maintenance.

Seasonal Maintenance Tips

Preparing for Harsh Conditions: Different seasons bring different challenges. In colder months, winterization is crucial to prevent freezing and damage to your equipment. This may involve draining fluids, insulating components, or using antifreeze solutions. In hotter climates, ensure your equipment is prepared to handle higher temperatures by checking cooling systems and fluid levels. Seasonal changes require adjustments in both pump and dredge equipment maintenance routines.

Storage and Downtime: If your equipment will be out of service for an extended period, proper storage is essential. Follow manufacturer guidelines for preparing your pump and dredge equipment for storage, including cleaning, draining fluids, and protecting exposed components. When restarting equipment after downtime, perform a thorough inspection to ensure everything is in working order, addressing any dredge equipment troubleshooting as needed. Proper storage is a crucial element of seasonal pump maintenance.

Inspecting and Replacing Worn Parts: Seasonal changes often bring added stress to your equipment, making it the perfect time to inspect and replace any worn parts. Using original equipment manufacturer (OEM) parts is crucial for maintaining the integrity and performance of your equipment and ensuring proper dredge machinery maintenance. Replacing worn parts is also a critical aspect of long-term pump maintenance.

Long-Term Maintenance Strategies

Creating a Maintenance Schedule: A well-organized maintenance schedule is the backbone of a successful maintenance program. Develop a schedule that incorporates daily, weekly, monthly, and seasonal tasks, as well as any manufacturer-recommended procedures. Sticking to this schedule helps ensure that no maintenance task is overlooked, leading to more efficient pump maintenance and dredge equipment maintenance.

Training and Skill Development: It is critical to ensure that your team is well-trained in maintenance procedures. Regular training sessions and access to resources for skill development can help your staff stay up-to-date with the latest maintenance techniques and best practices, ensuring effective dredge machinery maintenance. Training is also essential for implementing consistent and effective pump maintenance.

Utilizing Maintenance Software: Maintenance management software can be an invaluable tool for tracking maintenance activities, scheduling tasks, and keeping detailed records. These systems can automate reminders and provide insights into the overall health of your equipment, making it easier to stay on top of pump and dredge equipment maintenance.

Troubleshooting Common Issues

Identifying Early Warning Signs: Being able to recognize early warning signs of potential problems is key to preventing major issues. Common indicators include unusual noises, vibrations, or drops in performance. Addressing these signs promptly can save you from more significant problems down the road and assist in dredge equipment troubleshooting. Recognizing early signs is also a key component of proactive pump maintenance.

Quick Fixes vs. Professional Repair: While some issues can be quickly fixed in-house, others may require professional repair. Knowing when to apply a quick fix and when to call in an expert is essential for maintaining the safety and reliability of your equipment, especially when dealing with complex dredge equipment troubleshooting. Understanding when to escalate a problem is crucial for both pump maintenance and overall equipment reliability.

Preventative vs. Reactive Maintenance: Preventative maintenance is about being proactive and addressing potential issues before they become significant problems. This approach is far more effective than reactive maintenance, which often leads to unexpected downtime and costly repairs. Adopting a preventative approach is central to successful pump maintenance and dredge equipment maintenance.

Conclusion

Regular pump maintenance is the key to prolonging the life of your pump and dredge equipment. By following these tips and implementing a comprehensive maintenance program, you can ensure that your equipment remains reliable, efficient, and ready to perform when you need it most. Don’t wait for problems to arise—take a proactive approach to pump maintenance and dredge equipment maintenance and enjoy the benefits of a well-maintained system for years to come.