Sediment buildup in rivers, lakes, ports, and industrial water bodies poses ongoing challenges for navigation, flood control, and environmental restoration. To combat these issues, sediment removal through dredging has become a critical component of waterway maintenance and marine construction projects. At the heart of these operations is the dredge boat—a specialized vessel designed to excavate, transport, and discharge sediment with precision and efficiency.

Whether it’s clearing silt from navigation channels or restoring ecological balance in a shallow lagoon, the dredge boat plays an essential role in both industrial and environmental applications. With advancements in technology, modern dredging vessels are equipped with high-performance pumps, GPS-based positioning systems, and automated controls to increase accuracy and productivity.

In this blog, we explore how the efficient operation of a dredging boat leads to reduced fuel use, minimal environmental impact, and significant cost savings over time. We’ll also examine the differences in equipment types, from cutter suction systems to barge-mounted excavators, and how a dredger barge supports dredge operations in both shallow and deepwater settings. Regardless of the scale, understanding how to optimize dredger barge performance is vital for successful sediment management. Let’s dive into best practices that can transform your dredging project into a streamlined and sustainable operation.

Understanding Dredge Boat Configurations

Understanding the different configurations and components of a dredge boat is key to selecting the right equipment for your sediment removal project. Various types of dredging boats are available to match specific environmental conditions, sediment types, and operational goals.

One of the most common types is the cutter suction dredge boat, which uses a rotating cutterhead to break up compacted sediment before suctioning it through a pipeline. This method is effective for large-scale projects requiring deep and continuous dredging, such as channel deepening or port maintenance.

Another popular type is the auger dredging boat, often used in environmental applications. This vessel features a horizontal rotating auger that disturbs sediment with minimal turbidity, making it ideal for sensitive habitats and shallow water bodies like ponds, lakes, or reservoirs.

Bucket-ladder dredgers are more traditional but are still used in specific applications. They operate by using a series of buckets mounted on a continuous chain that excavates sediment mechanically. These systems are robust and capable of handling dense or coarse materials, though they are less efficient in finer sediment environments.

It’s also important to distinguish between different vessel classifications. A dredge boat typically refers to a self-contained, often self-propelled unit that can navigate to and from the dredging site. In contrast, a dredger barge is usually a flat-decked platform equipped with dredging machinery but requires tug assistance for transport. Dredger barges are preferred when working in confined areas or when deploying modular equipment for offshore or nearshore operations.

Regardless of the type, most dredging boats share common components: a suction pipe that draws sediment, a cutterhead or auger to loosen material, a powerful slurry pump for sediment transport, and a control cabin where operators monitor and manage the process. Some advanced models also feature GPS and sonar systems for precision dredging.

Selecting the right dredge boat configuration ensures efficient operation, minimized environmental impact, and optimal results tailored to your specific project requirements.

Site Assessment and Pre-Dredging Planning

Before any dredge boat is deployed, thorough site assessment and planning are essential to ensure project success. Proper pre-dredging evaluation not only optimizes efficiency but also helps prevent environmental violations and costly delays.

The first step in pre-dredging planning involves bathymetric surveys and sediment sampling. Bathymetric surveys use sonar or GPS-based equipment to map the underwater terrain, giving operators a clear understanding of depth variations and sediment accumulation. Sediment sampling helps determine the type and composition of material to be removed—whether it’s fine silt, clay, sand, or contaminated sludge. This information is vital in selecting the right dredge boat and planning the appropriate dredging method.

Next, environmental considerations must be addressed. Dredging can stir up contaminants or disrupt aquatic ecosystems, so identifying potential environmental risks early is crucial. Many projects require permits from local, state, or federal agencies. These may involve water quality standards, sediment disposal regulations, and wildlife impact assessments. Without proper documentation, your dredging boat operation could face regulatory shutdowns or legal issues.

Once environmental factors are understood, the project team can define specific dredging goals, such as required depth, sediment volume to be removed, and the total area of coverage. Clear goals help establish operational timelines and provide benchmarks for performance and efficiency.

With goals in place, equipment selection becomes more targeted. A compact dredging boat might be suitable for a shallow, environmentally sensitive pond, while a powerful dredge boat with extended reach may be required for deep harbor restoration. In larger-scale or modular projects, a dredger barge outfitted with interchangeable equipment may offer the most flexibility and scalability.

Understanding site-specific challenges, including access limitations, sediment type, and water flow conditions, is key to deploying the right combination of equipment. Whether using a single dredge boat or a combination of dredger barge systems, informed planning ensures a safer, faster, and more cost-effective dredging operation tailored to your unique site conditions.

Dredging Techniques and Operational Best Practices

Efficient dredging operations depend heavily on technique and execution. Once the right dredge boat or dredger barge is in place, following best practices ensures optimal sediment removal, minimal environmental impact, and smoother project timelines.

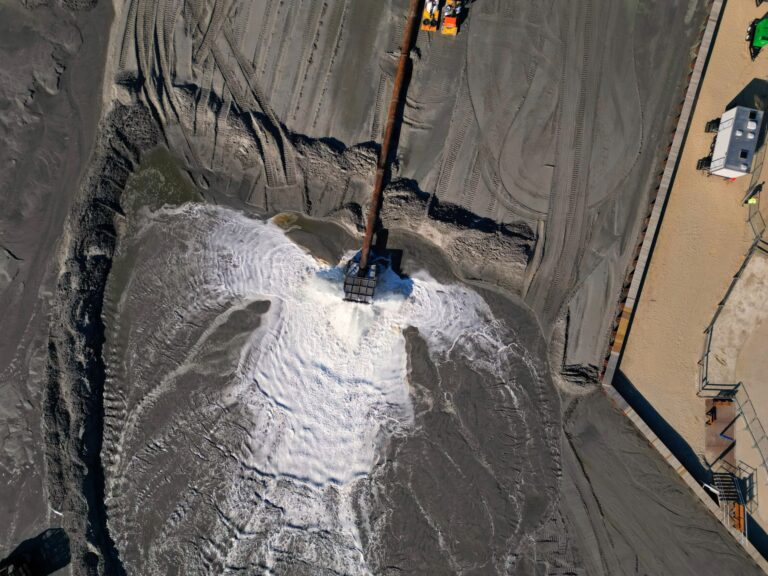

One of the first operational steps is the proper anchoring and positioning of the dredge boat. Accurate positioning ensures that the cutterhead or suction inlet is aligned with the designated dredging area. Operators often use spud poles or winch systems combined with GPS to maintain precision during movement. A well-anchored dredging system also helps reduce unnecessary swings or drift, which can waste fuel and time.

Maintaining optimal suction head and pump efficiency is critical. Excessive suction lift can reduce pump performance and increase wear on components. Ensuring the intake is submerged adequately while maintaining a steady material flow helps extend the life of the pump and maximize throughput. For deeper sites, using a booster pump setup on a dredger barge can help maintain consistent pressure and efficiency.

To protect water quality, minimizing turbidity and sediment resuspension is a key focus. Turbidity can be managed through controlled dredging speeds, use of specialized cutterheads, and the deployment of silt curtains around the work zone. For environmentally sensitive projects, a slow and steady approach with minimal agitation is often preferred, especially when operating a dredging boat in shallow or ecologically fragile waters.

Modern dredging boats are increasingly equipped with real-time monitoring and automation tools. These include GPS-guided dredging, sonar depth sensors, flow meters, and pump load monitors. These technologies improve precision, reduce guesswork, and allow for better tracking of productivity and sediment movement in real-time.

Choosing between hydraulic and mechanical dredging techniques often depends on project conditions. A hydraulic system, typically used on a dredge boat, is better for soft sediment and large volumes over longer distances. Mechanical dredging, such as using a clamshell bucket mounted on a dredger barge, is preferred for compacted materials and precise excavation needs.

By applying these best practices across all operational stages, a well-managed dredge boat operation can significantly improve results while reducing downtime, costs, and environmental disruption.

Safety and Crew Training

Safety is a critical component of every dredge boat operation. Whether you’re managing a large-scale marine excavation or a small inland waterway project, ensuring the safety of your crew and equipment is essential to maintaining productivity, avoiding delays, and preventing costly accidents. A well-trained team and clear safety protocols form the foundation of any successful dredging boat operation.

Onboard safety procedures for operating a dredger barge include daily safety briefings, proper use of personal protective equipment (PPE), hazard identification, and equipment lockout/tagout protocols. Operators must be aware of potential risks such as entanglement in moving parts, pump pressure hazards, slips and falls on wet decks, and electrical systems near water. Regular walkthroughs and safety checklists should be part of every shift to ensure the work area remains hazard-free and that all systems are functioning correctly.

Training and certification are just as important as physical safety measures. Dredge operators must have hands-on experience and meet relevant maritime or industrial training standards. Certifications in dredge operation, confined space entry, first aid, and environmental awareness are often required, depending on the scope of the project. Cross-training multiple crew members also provides operational flexibility and ensures that safety protocols are followed even when shifts change or personnel rotate.

Emergency response planning is another vital area of focus. Every dredge boat should have a documented and rehearsed emergency response plan that includes actions for fire, flooding, man-overboard situations, and equipment failures. Conducting regular safety drills ensures the crew is prepared to respond quickly and effectively in case of an incident. Drills should be recorded, evaluated, and used as a learning tool to improve overall safety readiness.

Ultimately, a culture of safety promotes crew confidence, increases efficiency, and reduces liability. Whether operating a modern dredge boat or a manually controlled dredger barge, prioritizing safety and investing in continuous crew training ensures operations run smoothly while protecting people, equipment, and the environment.

Environmental Considerations

Environmental stewardship is a fundamental aspect of modern dredging operations. As demand grows for sediment removal in sensitive aquatic environments, operators must implement effective practices to minimize ecological disruption. Responsible use of a dredge boat requires more than technical precision—it also demands proactive planning to reduce the project’s environmental footprint.

One of the most critical concerns during dredging is turbidity, or the clouding of water caused by disturbed sediment. Elevated turbidity levels can harm fish, smother aquatic vegetation, and transport pollutants downstream. To mitigate this, operators often deploy silt curtains or other containment systems around the dredge boat work zone. These physical barriers reduce the spread of suspended particles, allowing sediment to settle naturally before leaving the site.

Noise and emissions control is another priority. Dredging activities can produce underwater noise that disrupts aquatic wildlife, particularly in shallow or ecologically sensitive areas. Using quieter, low-RPM engines and sound-dampening equipment can help reduce the acoustic impact. Additionally, upgrading to fuel-efficient engines or electric drive systems can significantly cut down on greenhouse gas emissions and improve fuel economy. Routine engine maintenance also plays a vital role in reducing exhaust pollutants and maintaining environmental compliance.

Operators must also ensure that all dredging activities align with environmental regulations. In the U.S., compliance with Environmental Protection Agency (EPA) guidelines and permits from local water authorities is mandatory. These regulations govern everything from sediment disposal methods and water quality standards to protected species and habitat disturbance. Projects often require pre-dredging environmental impact assessments and post-dredging monitoring to ensure compliance throughout the operation.

Using GPS-guided systems and real-time dredging data not only improves operational accuracy but also minimizes over-dredging and the unnecessary disturbance of aquatic ecosystems. This precision helps maintain ecosystem balance while achieving project goals efficiently.

By integrating environmental best practices into day-to-day operations, dredge boat operators can meet performance targets while protecting surrounding ecosystems. A thoughtful, compliance-driven approach not only reduces legal and reputational risk but also contributes to the long-term sustainability of the waterways being restored or maintained.

Conclusion

Efficient dredging boat operations are the cornerstone of successful sediment removal projects. From accurate site assessments to best-in-class equipment handling, every step impacts the overall performance, cost-efficiency, and environmental footprint of your dredging efforts. Whether you’re working on a small inland pond or a major marine channel, the right strategy and the right dredge boat make all the difference.

Smart planning, combined with disciplined execution, minimizes project delays, reduces fuel consumption, and protects surrounding ecosystems. Incorporating real-time monitoring tools, adhering to safety and environmental protocols, and training your crew effectively ensures a streamlined operation with lasting results.

If you’re planning a dredging project and want to maximize efficiency without compromising compliance, our team is here to help. Contact us today for expert consulting, high-performance equipment rentals, or fully customized dredge boat solutions tailored to your site conditions and project goals. Let us help you turn your sediment challenge into a sustainable success.