Dredging is critical in many industries, including construction, mining, and environmental remediation. It involves removing or relocating sediments, debris, and other materials from bodies of water to maintain navigability, prepare for construction, or clean up environmental hazards. The success of a dredging project heavily relies on selecting the right equipment. Choosing dredge equipment that is not well-suited to the project can lead to inefficiencies, increased costs, and potential environmental damage. This blog will guide you through selecting the most suitable types of dredge equipment for your specific project needs.

Understanding Your Project Requirements

Project Type and Objectives

The first step in selecting the right equipment is clearly defining your dredging project’s type and objectives. Are you undertaking excavation, environmental cleanup, or sediment removal? Understanding the primary purpose of the operation will help narrow down the types of dredge equipment options. For instance, excavation projects require robust equipment that can handle dense materials, while environmental cleanup operations prioritize equipment that minimizes disturbance to the ecosystem.

Once the project type is identified, defining the goals and expected outcomes is crucial. This could include the volume of material to be removed, the desired depth, or specific environmental restoration targets. A well-defined goal ensures that choosing dredge equipment aligns with the project’s demands, preventing over- or under-performance. Selecting equipment that fits these specific goals is essential to the overall success of the project.

Material Characteristics

Different dredging projects involve varying types of materials. Assessing the characteristics of the material to be dredged is essential in choosing dredge equipment. Materials such as sand, gravel, clay, and silt each have different properties that can impact the efficiency and effectiveness of equipment.

For example, materials with higher density or abrasiveness, like gravel, require dredges with greater power and durability. Conversely, softer materials like silt might be handled more effectively by equipment designed for precision and minimal environmental impact. Understanding the material characteristics will ensure the equipment can handle your dredging operations efficiently without unnecessary wear and tear.

Site Conditions

The physical conditions of the project site also play a significant role in choosing dredge equipment. Water depth, access points, and environmental considerations must be thoroughly evaluated. For example, deeper water may necessitate dredges with greater reach, while restricted access areas might require more compact or portable equipment.

Additionally, environmental factors such as local wildlife, vegetation, and water currents should be considered to minimize the impact of dredging operations. Equipment that can operate efficiently within these constraints will help ensure the project’s success without causing undue harm to the surrounding environment.

Types of Dredge Equipment

Mechanical Dredges

Mechanical dredges are commonly used in projects where precise material removal is required. They use mechanical means to scoop or excavate material from the seabed or riverbed. Types of dredge equipment in this category include bucket dredges and backhoe dredges.

Mechanical dredges are ideal for projects involving dense or coarse materials, such as gravel or compacted sediment. Their robust design allows them to handle materials that may be difficult for other types of dredge equipment to manage.

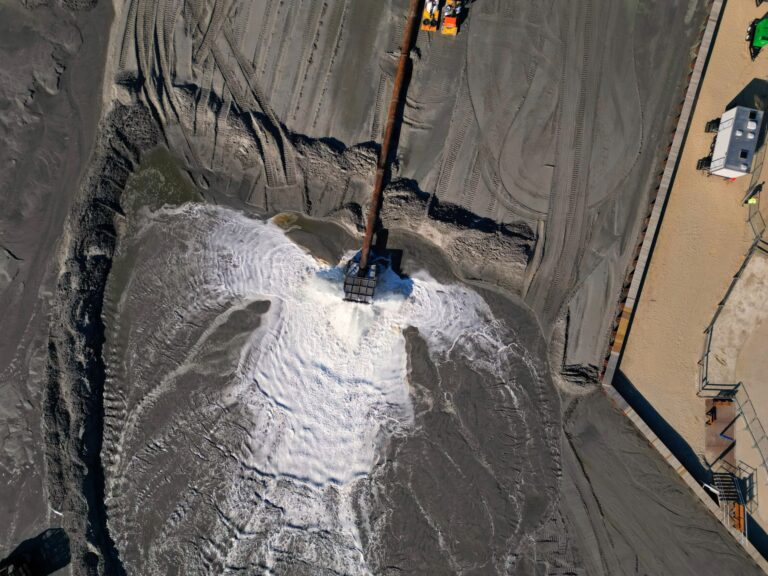

Hydraulic Dredges

Hydraulic dredges, such as cutter suction dredges and hopper dredges, use a combination of water pressure and suction to remove and transport sediment. These types of dredge equipment are suitable for projects involving loose or fine materials like sand or silt.

Hydraulic dredges are highly efficient for large-scale projects where the material must be transported over long distances, such as in beach nourishment or port deepening projects. They offer flexibility in handling different material types and can operate continuously, making them a preferred choice when choosing dredge equipment for extensive dredging operations.

Specialty Dredges

Specialty dredges are designed for unique or challenging dredging scenarios. Examples include auger dredges and environmental dredges. Auger dredges are used for precision dredging in shallow water or confined areas, while environmental dredges are designed to minimize the resuspension of contaminated sediments.

Specialty dredges should be considered when standard mechanical or hydraulic types of dredge equipment are not suitable for the specific needs of a project. Their specialized design allows them to address unique challenges effectively, ensuring that even the most complex dredging projects can be completed successfully.

Key Factors to Consider in Equipment Selection

Dredging Depth and Volume

When choosing dredge equipment, it’s essential to match its capabilities with the required dredging depth and volume. Equipment that can’t reach the necessary depth or handle the required volume will lead to inefficiencies and increased project costs.

Accurately calculating and estimating dredging volumes is crucial. This information will help determine the size and power of the equipment needed to complete the dredging project within the desired timeframe.

Environmental Impact and Regulations

Dredging projects are often subject to strict environmental regulations. Understanding these regulations and choosing dredge equipment that minimizes environmental disruption is critical. For example, some dredges have features that reduce turbidity, which is important in projects near sensitive ecosystems.

Complying with environmental regulations ensures legal compliance and contributes to the project’s sustainability, preserving the natural habitat for future generations.

Cost and Budget Considerations

While it’s important to choose dredging equipment that meets project requirements, it’s equally important to consider cost and budget constraints. Balancing equipment efficiency with budget considerations involves considering both the upfront cost of the equipment and long-term expenses such as maintenance and fuel efficiency.

Opting for equipment that offers the best value rather than the lowest price can save money in the long run, ensuring that the project stays within budget while maintaining high operational standards.

Mobility and Access

Mobility and access are often overlooked factors when choosing dredge equipment. If a project site is difficult to access or requires equipment to be moved frequently, selecting portable or easily transportable dredging equipment is crucial. Equipment that fits the project’s access limitations ensures smooth operation and reduces the risk of delays or additional costs due to transportation challenges.

Tips for Making the Final Decision

Consulting with Experts

Choosing dredge equipment can be complex, and consulting with industry experts can provide invaluable insights. Dredging consultants can advise on the best equipment for your specific project and help you navigate any challenges.

Working with reputable dredging consultants ensures that your dredging equipment selection is informed by experience and expertise, reducing the risk of costly mistakes.

Testing and Trial Runs

Before fully committing to a piece of dredging equipment, conducting a small-scale test or trial run is wise. This allows you to evaluate the equipment’s performance in real-world conditions and make necessary adjustments.

Testing ensures that the chosen dredge equipment is well-suited to the project, reducing the risk of operational issues once full-scale dredging begins.

Future-Proofing Your Equipment Selection

When selecting equipment for dredging, it’s important to consider not only the immediate needs of the project but also future requirements. Choosing equipment that offers flexibility and scalability ensures that it can be used for future projects, maximizing your investment.

Future-proofing your equipment selection means considering potential changes to the project scope or objectives and choosing dredge equipment that can adapt to these changes.

Conclusion

Recap of Key Points

Choosing the right dredge equipment is critical to the success of any dredging project. By understanding your project requirements, considering material characteristics, evaluating site conditions, and selecting the appropriate types of dredge equipment, you can ensure your project is completed efficiently and effectively.

Final Recommendations

Thorough research and expert consultation are essential in the equipment selection process. By prioritizing these steps, you can make informed decisions that will contribute to the overall success of your project.

If you need personalized recommendations or further guidance in choosing dredge equipment for your project, please contact us. Our team of experts is ready to help you navigate the equipment selection process and ensure the success of your dredging project.