Industrial pumps are indispensable in various large-scale projects, providing essential services that ensure efficiency, reliability, and safety. These pumps are crucial for smooth operations from construction sites to manufacturing plants. This blog will explore the benefits of industrial pumps, the different types, and how they contribute to the success of large-scale projects.

Understanding Industrial Pumps

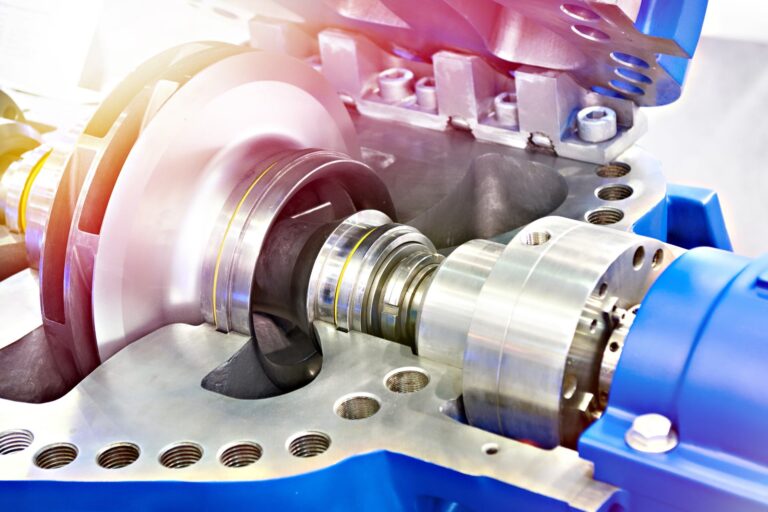

Industrial pumps are mechanical devices that move liquids, slurries, or gases through a system. They are used in various industries, including construction, mining, manufacturing, and water treatment. The primary function of these pumps is to transfer fluids from one location to another, often against gravity, pressure differences, or over long distances.

Critical Benefits of Industrial Pumps

Efficiency and Reliability

One of the primary industrial pump benefits is their efficiency and reliability. These pumps are designed to handle large volumes of fluids quickly and consistently, minimizing downtime and ensuring that projects stay on schedule. Advanced engineering and materials have enhanced the durability of industrial pumps, allowing them to operate under harsh conditions without frequent maintenance or replacement.

Versatility

Industrial pumps are versatile and can be customized to meet the specific needs of different projects. Whether it’s moving water, chemicals, sludge, or other materials, an industrial pump type is suited for the job. This adaptability makes them invaluable in various industries, from agriculture to oil and gas.

Cost-Effective Operations

Industrial pumps help reduce operational costs by improving the efficiency of fluid transfer processes. They minimize energy consumption and require less manual intervention, leading to significant cost savings over time. Additionally, their robust construction means fewer breakdowns and lower maintenance expenses.

Environmental Protection

Industrial pumps contribute to environmental protection by enabling the safe and efficient handling of hazardous materials. Pumps designed for chemical industries, for instance, ensure that toxic substances are transferred without leaks or spills, preventing environmental contamination. Pumps help process and clean water in wastewater treatment plants, promoting sustainable water management practices.

Types of Industrial Pumps

Dredging Pumps

Dredging pumps are specifically designed to remove sediments, sand, and other materials from the bottom of water bodies. They are essential in large-scale dredging projects such as harbor deepening, river channel maintenance, and land reclamation. Dredging pumps’ benefits include their ability to handle large volumes of material efficiently and their robustness in harsh underwater environments. Examples of projects utilizing dredging pumps include the expansion of ports and the restoration of navigable waterways.

Dewatering Pumps

Dewatering pumps remove unwanted water from construction sites, mines, and other areas where water accumulation can hinder operations. These pumps are crucial for maintaining dry and safe work environments. Typical applications of dewatering pumps include basement and trench dewatering, flood control, and groundwater control in mining operations. The advantages of dewatering pumps lie in their ability to operate continuously and their effectiveness in preventing water-related delays and hazards.

Slurry Pumps

Slurry pumps are designed to handle abrasive and viscous materials, making them ideal for transferring slurries in mining, mineral processing, and wastewater treatment industries. These pumps are built to withstand the wear and tear caused by the solids in the slurry, ensuring long-term reliability and performance. Industries that benefit from slurry pumps include mining operations where ore and tailings must be transported and industrial plants where thick mixtures must be processed and moved efficiently.

Selecting the Right Industrial Pump for Your Project

Choosing the right industrial pump for a specific project involves considering various factors, including the type of fluid to be moved, the required flow rate, and the operating environment. Understanding project requirements and fluid properties is crucial for selecting an appropriate pump type. Matching the pump to the project’s specific needs ensures optimal performance and cost-effectiveness.

Conclusion

Industrial pumps are indispensable for large-scale projects across various industries. Their efficiency, reliability, versatility, cost-effectiveness, and environmental benefits make them critical components of modern industrial operations. Understanding the different types of industrial pumps, such as dredging, dewatering, and slurry, helps select the right pump for specific needs, ensuring optimal performance and project success. Whether it’s a construction site, a mining operation, or a water treatment facility, industrial pumps play a vital role in maintaining smooth and efficient operations.

Visit Pump and Dredge Direct for more information on industrial pumps and to find the right solution for your project.