Maintaining waterways is essential for preserving environmental health, supporting navigation, and protecting infrastructure. Over time, sediment buildup, debris accumulation, and environmental changes can restrict water flow, reduce water quality, and create hazards for marine traffic. Effective waterway maintenance ensures that rivers, lakes, harbors, and coastal areas remain navigable and ecologically balanced. One of the most effective solutions for maintaining waterways is using a floating dredge.

A floating dredge is designed to remove sediment, debris, and other obstructions from water bodies while operating directly on the water’s surface. Unlike traditional land-based dredging equipment, floating dredges can access hard-to-reach areas, making them ideal for shallow or remote waterways. This flexibility allows for more precise sediment removal, improving overall water quality and flow. Additionally, using a floating dredge enhances efficiency by minimizing the need for repositioning and reducing operational costs.

In some cases, a floating gold dredge is used for mining valuable materials such as gold from riverbeds. These dredges are specifically designed to capture fine gold particles while maintaining the integrity of the waterway. Furthermore, the use of dredge pipe floats helps keep the discharge pipeline stable and afloat, allowing for efficient transport of dredged material over long distances. This combination of versatility and efficiency makes floating dredges a valuable tool for waterway maintenance.

What is a Floating Dredge?

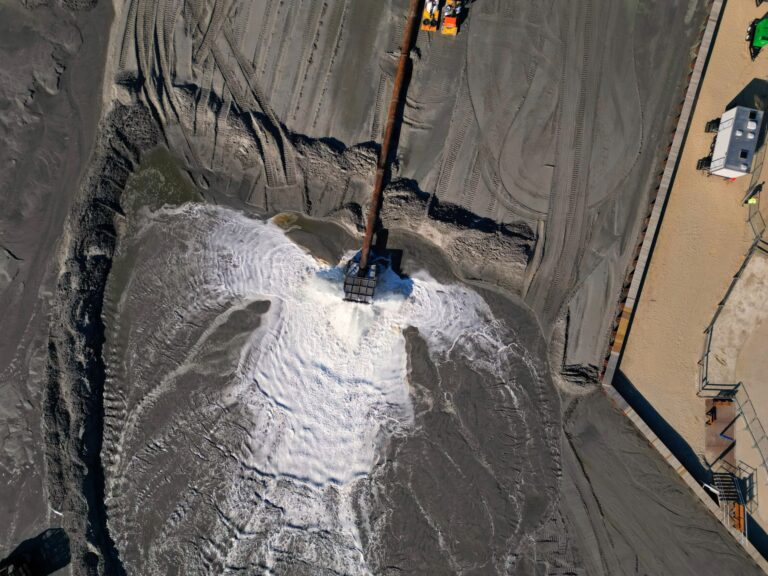

A floating dredge is a highly specialized piece of equipment used for removing sediment, debris, and other materials from the bottom of water bodies such as rivers, lakes, harbors, and coastal areas. Unlike land-based dredging equipment, which is limited by terrain and water access, a floating dredge operates directly on the water’s surface. It is supported by pontoons or other flotation devices, which allow it to maintain stability and maneuverability even in challenging water conditions. This makes it an ideal solution for maintaining navigability, improving water quality, and managing sediment buildup in hard-to-reach or shallow waterways.

The key components of a floating dredge include a cutter head or suction head, which is used to loosen and extract sediment from the waterbed. Once the sediment is broken up, a powerful pump transfers the material through a pipeline to a designated discharge area. Dredge pipe floats play a critical role in this process by keeping the pipeline stable and afloat, ensuring smooth and efficient transport of dredged material over long distances. The control system of a floating dredge allows operators to adjust dredging depth and positioning with precision, enhancing overall efficiency and minimizing environmental impact.

There are several types of floating dredges, each suited for specific applications. A cutter suction dredge uses a rotating cutter head to loosen sediment before suctioning it through the pipeline. This type of dredge is ideal for compacted or rocky sediment. An auger dredge employs a rotating screw mechanism to extract sediment, making it highly effective in removing fine materials from riverbeds and lakes. Hydraulic dredges, on the other hand, use high-pressure water jets to dislodge and transport sediment, providing a more delicate solution for sensitive ecosystems.

Floating dredges are widely used in mining operations and waterway maintenance. A floating gold dredge is specifically designed to extract fine gold particles from riverbeds and other sediment-rich environments. These dredges are equipped with specialized recovery systems that enhance gold capture rates while minimizing material loss. The combination of efficiency, mobility, and precision makes a floating dredge an indispensable tool for both waterway maintenance and gold mining. Compared to land-based dredging methods, a floating dredge offers greater versatility and improved performance in diverse aquatic environments.

Benefits of Using a Floating Dredge for Waterway Maintenance

Enhanced Efficiency and Performance

One primary advantage of using a floating dredging system for waterway maintenance is its ability to operate continuously without frequent repositioning. Unlike land-based dredging equipment, which often requires adjustments to account for shifting sediment and changing water levels, a floating unit remains stable and operational even in challenging water conditions. This allows for higher productivity and reduced downtime, making it a cost-effective solution for large-scale dredging projects.

Floating dredging systems are highly effective in handling various sediment types, including silt, sand, clay, and gravel. Their ability to process different materials without sacrificing performance ensures consistent production rates and efficient material handling. The stability provided by the floating platform allows for precise sediment removal, which helps reduce the risk of environmental disturbance and keeps waterways clear and navigable. Maintaining steady production rates also enables project managers to plan more effectively, minimizing delays and controlling overall costs.

The use of dredge pipe floats significantly enhances operational efficiency. These floats keep the discharge pipeline stable and afloat, preventing it from sinking or becoming misaligned. This ensures a consistent and uninterrupted flow of dredged material from the worksite to the discharge area, improving overall material transport efficiency. Dredge pipe floats also help reduce stress on the pipeline, minimizing wear and tear and extending the lifespan of the equipment. This results in lower maintenance costs and improved long-term operational performance.

A floating gold dredge is particularly effective at extracting fine gold particles from sediment in mining operations. Its ability to operate in remote and shallow waterways allows for increased recovery rates and improved efficiency. The precision and consistent material handling offered by a floating gold dredge make it a valuable tool for gold mining, ensuring minimal material loss and maximum profitability.

Access to Hard-to-Reach Areas

Dredging vessels are highly effective in accessing shallow and remote waterways that are difficult or impossible to reach with land-based equipment. Their ability to float allows them to navigate narrow channels, shallow rivers, and coastal areas with ease.

This makes them ideal for maintaining lakes, rivers, and harbors where sediment buildup can restrict water flow and hinder navigation. A floating dredger can adapt to varying water levels, making it an excellent solution for seasonal or tide-dependent projects. Its ability to work in confined spaces without compromising efficiency ensures that even the most difficult-to-reach areas can be properly maintained.

A floating gold dredge is particularly valuable in mining operations in remote riverbeds and isolated water bodies. These systems are designed to extract fine gold particles from sediment while maintaining environmental integrity. Their ability to operate in challenging locations increases gold recovery rates and allows for more effective resource extraction.

Cost-Effective Operation

Marine-based dredging equipment offers significant cost advantages over land-based systems. Its ability to operate continuously without needing to be repositioned reduces labor and fuel costs. Since a floating system can handle various sediment types and water depths without requiring additional equipment, its overall operational expenses are lower. This makes it a more practical and efficient solution for large-scale dredging operations.

Dredge pipe floats also contribute to cost savings through efficient material handling. The steady flow of dredged material through the pipeline reduces downtime and minimizes the risk of blockages, which can otherwise lead to costly delays. Additionally, the enhanced stability provided by dredge pipe floats reduces the need for frequent repairs and maintenance, further lowering overall expenses.

Faster project completion also leads to reduced costs. A dredging vessel can complete projects more quickly than traditional equipment, minimizing disruption to local ecosystems and reducing labor costs. In mining operations, a floating gold dredge provides additional cost advantages by improving recovery rates and reducing the time needed to process sediment. The ability of a floating gold dredge to extract fine gold particles efficiently increases profitability and makes it a valuable asset for mining companies. These cost efficiencies make floating dredgers an attractive option for large-scale waterway maintenance and mining projects.

Environmental Benefits

Floating dredgers are designed to minimize environmental impact while maintaining high operational efficiency. One key advantage of a floating system is its ability to reduce turbidity, which refers to the cloudiness of water caused by disturbed sediment. Lower turbidity levels help protect aquatic ecosystems by reducing stress on fish and other aquatic life.

Selective dredging capabilities allow operators to target specific sediment layers without disturbing underlying ecosystems. This is particularly valuable when removing contaminated material or restoring sensitive habitats. By carefully controlling the dredging depth and extraction method, operators can improve water quality and restore natural flow patterns without causing ecological damage.

Gold dredging systems are also designed with environmental protection in mind. Their ability to operate with minimal disturbance to the riverbed helps preserve the natural habitat while still achieving high recovery rates. The combination of efficient sediment removal and environmentally sensitive operation makes these systems a sustainable choice for waterway maintenance and resource extraction.

Versatility Across Applications

Floating dredging equipment is suitable for a wide range of applications, making it one of the most versatile tools for waterway maintenance. Its ability to handle different sediment types and adapt to varying water levels makes it ideal for:

- Port and harbor maintenance

- River and lake restoration

- Canal deepening

- Flood prevention and erosion control

Dredging systems’ compatibility with dredge pipe floats enhances their versatility. Pipe floats provide stability and flexibility during material transport, allowing operators to adjust the pipeline length and positioning to suit different project requirements. This adaptability makes floating dredging equipment an effective solution for both routine maintenance and complex dredging projects.

Simplified Material Handling with Dredge Pipe Floats

Efficient material handling is critical to the success of any dredging operation, and dredge pipe floats play a vital role in this process. By keeping the discharge pipeline afloat and stable, pipe floats prevent the pipeline from sinking or twisting, ensuring a consistent flow of dredged material.

Improved pipeline stability reduces stress on the pipeline, minimizing the risk of damage and extending the lifespan of the equipment. This also reduces downtime and maintenance costs, leading to higher operational efficiency.

Dredge pipe floats enhance the dredging system’s maneuverability. Operators can adjust the pipeline’s position to accommodate changing water levels or sediment conditions. This flexibility ensures that material transport remains efficient and uninterrupted, even in challenging working environments.

Increased Recovery Rates with Floating Gold Dredges

Floating gold dredges are specifically designed to improve gold recovery rates from riverbeds and sediment deposits. Their ability to operate in remote and hard-to-reach locations gives mining operators a significant advantage when working in isolated or rugged terrain.

A floating gold dredge is equipped with advanced recovery systems that capture fine gold particles with high precision. These systems include sluice boxes, riffles, and other specialized components designed to separate gold from sediment efficiently. The ability to operate continuously and adapt to different sediment types increases the overall recovery rate, making these systems highly effective for mining operations.

The portability and flexibility of a gold recovery dredge also enhance its performance in mining projects. Operators can easily move the system to different sites, ensuring consistent gold recovery without the need for major adjustments. This makes gold dredging equipment a valuable tool for both small-scale and large-scale mining operations.

Reduced Maintenance and Downtime

Floating dredging systems are designed for long-term use and minimal maintenance. Their durable construction and high-quality components reduce the risk of breakdowns and mechanical failures. The ability to perform routine maintenance on-site ensures that downtime is kept to a minimum.

Easy access to key components, such as the cutter head, pump, and control system, allows operators to perform quick repairs and adjustments. Dredge pipe floats further reduce maintenance needs by minimizing stress on the discharge pipeline and preventing damage from misalignment or tangling.

Lower maintenance costs and reduced downtime contribute to the overall efficiency and cost-effectiveness of marine-based dredging systems. The ability to operate continuously and adapt to different working conditions ensures consistent performance and long-term value for dredging projects.

Conclusion

Using a floating dredge for waterway maintenance offers numerous advantages, including enhanced efficiency, cost-effectiveness, and environmental benefits. Floating dredging systems can operate continuously without frequent repositioning, handle various sediment types, and easily access shallow or remote waterways. Their ability to maintain consistent production rates ensures faster project completion and lower operational costs.

Floating gold dredges further enhance performance by improving gold recovery rates in mining operations. Their ability to capture fine gold particles in remote and hard-to-reach areas increases profitability while minimizing environmental impact. Additionally, dredge pipe floats play a critical role in maintaining pipeline stability and improving material transport efficiency. By reducing stress on the pipeline and ensuring consistent material flow, dredge pipe floats contribute to smoother, more reliable dredging operations.

For those seeking to improve waterway maintenance or maximize mining efficiency, investing in a floating dredge is a smart and sustainable solution. Explore the benefits of modern dredging technology to enhance your next project’s success.