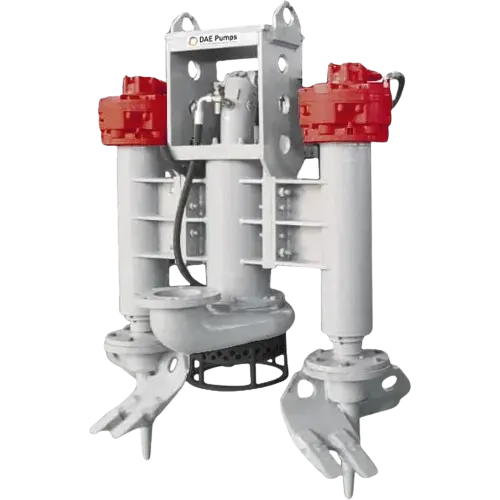

Growler 1000 Hydraulic

Versatile and Robust Dredge Pump

The DAE Pumps Growler 1000 Hydraulic Dredge Pump, equipped with dual side agitators, offers exceptional durability and reliability for transporting solids and various materials. This top-of-the-line dredge pump can move up to 2000 cubic meters of solids per hour, powered by its heavy-duty excavator agitators.

The Growler 1000 features non-clogging suction capabilities, allowing it to manage some of the most demanding dredging conditions. It can handle materials up to 3.9 inches in diameter and transport up to 70% solids by weight through a 16-inch discharge. As part of the DAE Pumps Growler Series, the hydraulic Growler 1000 is engineered for various dredging projects.

Adaptable for cable deployment or excavator mounting, the Growler 1000 can be easily modified to meet specific requirements. Its heavy-duty agitators efficiently excavate compact material, ensuring continuous feeding of the suction pump. The agitator and optional internal knife also chop organic materials like seaweed, grass, and other aquatic weeds, maintaining maximum suction power.

Dredging Operations and Applications

Dredging operations are essential for maintaining the functionality and safety of waterways, supporting a wide range of industrial and environmental needs. Utilizing advanced dredging equipment, these operations focus on the removal of sediment, silt, and debris to keep navigable waterways open and efficient. Maintenance dredging is a routine necessity for ports, harbors, and canals, ensuring that vessels can pass safely and that water flow remains unobstructed.

Beyond maintenance, dredging applications extend to land reclamation, where new land is created from bodies of water, and to mining operations that extract valuable minerals from underwater deposits. Environmental remediation projects also rely on powerful dredge pumps and equipment to remove contaminated or excess sediment, helping to restore ecosystems and improve water quality. Handling abrasive materials and high viscosity slurries requires robust pumps and durable equipment, making the right choice of dredging machinery critical for the success of any project.

Sediment Removal and Water Removal

Effective sediment removal is at the heart of successful dredging operations, playing a vital role in maintaining navigable waterways, preventing flooding, and enhancing water quality. Dredging equipment, such as high-capacity dredge pumps, is engineered to efficiently extract sediment, silt, and other materials from rivers, lakes, offshore areas, and other locations. Once removed, these materials are transported to designated disposal areas or prepared for reuse, supporting both environmental and operational goals.

Water removal is another key aspect, enabling the extraction of sediment and debris from submerged environments and facilitating the management of water levels in various settings. Regular maintenance of dredging equipment is crucial to prevent clogging and ensure reliable performance, minimizing downtime and maximizing the efficiency of sediment and water removal. By investing in quality pumps and adhering to maintenance schedules, operators can consistently improve water quality and maintain the integrity of critical waterways.

Dredging Projects and Industry Uses

Dredging projects are fundamental to a wide array of industries, underpinning global trade, infrastructure development, and environmental management. From expanding ports and deepening shipping channels to creating new land for construction and restoring natural habitats, dredging equipment is indispensable. In mining, dredges and excavators are used to extract minerals and transport them to other locations, while in construction, they help prepare sites and manage materials.

The versatility of modern dredging equipment allows it to handle a variety of materials and adapt to different project requirements. Whether the goal is to excavate sediment, transport it over long distances, or support land reclamation, powerful pumps and reliable machinery play a crucial role in ensuring project success. As industries continue to grow and evolve, the demand for efficient, high-performance dredging solutions remains strong.

Technical Specifications and Accessories

Selecting the right dredging equipment for your project involves careful consideration of technical specifications and available accessories. Key factors such as flow rate, pump material, and overall equipment durability determine how well a dredge pump will perform under specific conditions. For projects involving abrasive materials or high viscosity slurries, choosing pumps constructed from robust materials is essential for delivering exceptional performance and minimizing downtime.

Accessories like hoses and pipelines are integral to efficient dredging operations, enabling the smooth transport of sediment and other materials over varying distances. The choice of these components depends on factors such as sediment type, water depth, and compliance with environmental regulations. By matching the right equipment and accessories to your project’s unique requirements, you can ensure reliable operation and optimal results for any dredging application.

Safety Features and Regulatory Compliance

Safety and regulatory compliance are top priorities in any dredging operation, safeguarding both personnel and the environment. Modern dredging equipment is equipped with advanced safety features, including emergency shutdown systems and protective guards, to minimize risks and prevent accidents during operation. Adhering to environmental regulations is equally important, as it helps prevent issues such as pollution, erosion, and habitat disruption.

Regular verification and maintenance of dredging equipment are essential to ensure ongoing compliance with safety and environmental standards. By maintaining equipment in peak condition and following established protocols, operators can confidently manage the removal of sediment and other materials while upholding the highest standards of safety and environmental stewardship. This commitment not only protects resources but also supports the long-term success of dredging projects across industries.

Secure Your Growler 1000 Hydraulic Dredge Pump Today!

Discover the unmatched power and reliability of the DAE Pumps Growler 1000 Hydraulic Dredge Pump with its dual side agitators. This pump can handle up to 2000 cubic meters of solids per hour and materials up to 3.9 inches in diameter, perfect for transporting solids and various materials. Whether used as a cable-deployed or excavator-mounted dredge pump, the Growler 1000 is designed to quickly adapt to your project needs, showcasing its impressive capabilities and proven reliability.

Pump and Dredge Direct, the exclusive distributor of DAE Pumps in Canada, guarantees the local availability of the Growler 1000 and offers comprehensive support. Contact us today to request a quote or learn more about how the Growler 1000 can elevate your dredging operations. With our dependable support, you can be confident in your investment.

Key Features of the Growler 1000 Hydraulic Dredge Pump

- Highly durable and abrasion-resistant construction

- Dual side agitators for effective material break-up

- Available in multiple sizes: 3″, 4″, 6″, 8″, 10″, 12″, 14″, and 16″

- Capacity to handle up to 2000 cubic meters per hour

- Pumps up to 70% solids by weight

- Operational depth capability of up to 60 feet

- Robust motor providing strong torque and long life

- Interchangeable hard tooth agitator heads

We are authorized distributors for

Related Equipment

Dredging Equipment

We expose our wide range of top-class dredge equipment, which is designed for sand, gravel, and mineral extraction projects in Canada. Having the best features for maximum efficiency and profitability, our long-lasting and easy-to-use machinery is made of the best materials to guarantee the best performance and simplicity in maintenance.