Many water and wastewater systems in Canada struggle not because of treatment chemistry, but because of sediment, grit, and sludge buildup. Over time, these solids reduce flow capacity, block channels, and increase wear on pumps and equipment. The result is lower system efficiency and more unplanned maintenance.

For municipalities and industrial operators, this has become a growing wastewater management issue. Lagoons lose usable volume, intake areas fill with sediment, and heavy rainfall eventsincreasee solidsloading ino already stressed systems. When solids are not managed properly, even well-designed treatment plants begin to underperform.

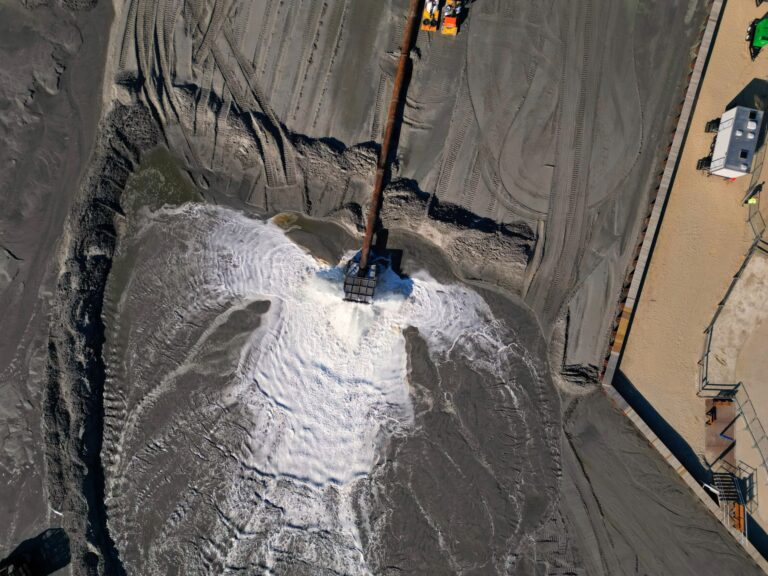

This is where Canada water treatment dredging becomes important. Removing accumulated solids helps restore capacity, improve flow, and reduce operational stress on treatment systems. Dredging is no longer only a large one-time project. It is increasingly used as a routine maintenance approach.

Using practical Canadian dredging solutions, along with the right pumping equipment, enables operators to manage solids more effectively and keep water and wastewater systems running as intended.

Key Wastewater and Water Treatment Challenges Facing Canadian Systems

Across Canada, many water and wastewater facilities face similar operational problems. These issues are not always caused by poor design. In most cases, they develop slowly as solids build up and system conditions change over time.

Loss of Lagoon and Basin Capacity

Wastewater lagoons and settling basins are designed to hold solids, but without regular removal, sludge accumulation reduces usable volume. As capacity drops, retention time decreases, and treatment performance becomes harder to control. This is a common wastewater management issue for small and mid-sized communities, especially where lagoons are the primary treatment method.

Sediment Build-Up in Intakes and Channels

Sand, silt, and debris often settle in intake structures, pump sumps, and open channels. This restricts flow and forces the pumps to operate above the designed level. Over time, it increases energy use, causes uneven loading, and leads to frequent maintenance callouts. Many facilities rely on Canada water treatment dredging to clear these areas and restore normal flow conditions.

Increased Solids During Wet Weather Events

Heavy rainfall and snowmelt push large volumes of water and solids into sewer systems. In combined sewer areas, stormwater carries grit and debris directly into wastewater infrastructure. These sudden solids loads strain pumping systems and reduce treatment stability, making wastewater management more reactive and less predictable.

Equipment Wear from Abrasive Materials

Solids such as sand and grit are highly abrasive. As they repeatedly pass through the pumps, they accelerate wear on impellers, casings, and seals. This results in a shorter equipment lifetime, higher sparepartst costs, and increased downtime. Addressing solids upstream through Canadian dredging solutions helps reduce this long-term damage.

Access and Seasonal Operating Constraints

Canada’s climate adds another layer of difficulty. Short construction seasons, cold temperatures, and limited site access make emergency work expensive and disruptive. Planned Canada water treatment dredging and pumping programs allow operators to manage solids during suitable windows rather than reacting under pressure.

How Targeted Dredging and Pumping Improves Wastewater Management

For many Canadian operators, solids are a constant source of frustration. Systems that once ran smoothly begin to struggle, not because of poor design, but because sediment and sludge gradually reduce capacity. When this happens, teams are forced into reactive decisions, tighter operating margins, and increased risk during peak flow events.

This is where Canada water treatment dredging provides real operational relief. Removing accumulated solids from lagoons, basins, and channels restores usable volume and provides operators with confidence to manage flows. Instead of working around limitations, facilities regain control over treatment performance.

Effective wastewater management also depends on reducing stress on pumping equipment. When heavy solids accumulate, pumps wear faster, clog more often, and require constant attention. Targeted dredging upstream changes this dynamic. Cleaner flow means fewer interruptions, longer equipment life, and maintenance that can be planned rather than rushed.

Pumping solutions designed for high-solids material complete the picture. Slurry, dredge, and dewatering pumps enable operators to safely and efficiently move difficult materials, even under tight timelines. This combination of dredging and pumping makes solids control manageable rather than an ongoing operational burden.

For Canadian facilities operating under seasonal constraints and regulatory pressure, proven Canadian dredging solutions deliver what matters every day: stability. When solids are managed properly, systems run more predictably, staff workloads become more manageable, and long-term planning becomes possible again.

Where Pump and Dredge Direct Solutions Support Canadian Facilities

For many water and wastewater teams, the challenge is not knowing what needs to be done, but finding equipment that actually works in real site conditions. Material varies. Access is limited. Timelines are tight. When equipment is not properly matched to the application, solids removal becomes more difficult than it should be.

This is where Pump and Dredge Direct comes into play. Their focus is not on one-size-fits-all systems, but on helping operators choose pumping and Canada water treatment and dredging solutions that match the materials, flow demands, and site constraints they face every day. This practical approach matters when systems are already under pressure, and there is little room for trial and error.

For Canada water treatment dredging, Pump and Dredge Direct supports applications such as lagoon desludging, basin cleaning, intake sediment removal, and channel maintenance. Slurry and dredge pumps are selected to handle thick sludge, abrasive grit, and high-solids material without constant clogging or premature wear. This reduces downtime and enables steady progress, even under challenging conditions.

In wastewater management, dewatering and bypass pumping solutions help facilities stay operational during maintenance, repairs, or wet-weather events. Reliable pumping allows teams to isolate problem areas, manage flows safely, and complete work without putting the entire system at risk.

What makes this support valuable is consistency. Canadian facilities operate within short seasonal windows and strict regulatory expectations. Having access to dependable Canadian dredging solutions, along with technical guidance and equipment support, gives operators confidence that solids issues can be addressed before they become emergencies.

Common Operating Scenarios and Practical Solids-Control Approaches

Every wastewater system is different, but the problems caused by solids tend to repeat. Operators across Canada face similar situations where sediment and sludge quietly limit performance until action becomes unavoidable. Addressing these issues early reduces stress on both systems and staff.

Lagoon Capacity Loss Before Peak Season

Over time, sludge accumulation reduces the effective volume of wastewater lagoons. As peak flow season approaches, operators often realize there is less buffer than expected. This creates pressure, especially when weather events arrive earlier or stronger than planned.

In this situation, Canada water treatment dredging allows facilities to remove settled sludge in a controlled way and recover lost capacity. When paired with the right pumping equipment, dredging can be scheduled within narrow operating windows, giving teams confidence heading into high-demand periods.

Intake and Channel Blockage Affecting Flow

Sediment build-up in intakes and channels is easy to overlook until flow restrictions become noticeable. When pumps begin to struggle or alarms increase, the impact is immediate. Crews are forced to respond quickly, often under less-than-ideal conditions.

Targeted dredging, combined with high-solids pumping, restores flow paths and reduces equipment strain. For wastewater management teams, this means fewer interruptions and a more stable operating environment.

Wet-Weather Solids Surges

Heavy rainfall and snowmelt can overwhelm sewer systems with large volumes of water and debris. These surges can overwhelm pumps and settling areas, increasing the risk of overflows and system instability. The pressure on operators during these events is real and time-sensitive.

Using temporary pumping and dredging as part of a planned response helps facilities stay ahead of these challenges. Proven Canadian dredging solutions enable teams to respond quickly without compromising safety or system integrity.

Abrasive Solids Driving Equipment Wear

Sand and grit move through systems every day. When left unmanaged, they shorten pump life and increase maintenance demands. Over time, this creates frustration and higher operating costs.

Removing abrasive solids upstream reduces wear and improves equipment performance. This approach supports longer service life and more predictable maintenance planning.

Managing Risk, Compliance, and Seasonal Constraints in Canada

Solids management is not only an operational concern. It also affects compliance, safety, and long-term planning. When sediment and sludge are ignored, risks increase quietly until they become difficult to control.

From a wastewater management perspective, reduced capacity and restricted flow raise the likelihood of overflows, process upsets, and emergency interventions. These situations place operators under pressure and leave little room for careful decision-making. Proactive planning reduces this risk and gives teams more control over system performance.

In Canada water treatment dredging, and risk management begin with understanding the material being removed. Sludge consistency, solids concentration, and potential contamination all influence how Canada water treatment dredging should be carried out and where material can be handled or disposed of. Addressing these factors early helps avoid delays and compliance issues later.

Seasonal constraints add another layer of challenge. Short work windows, cold temperatures, and limited access mean that reactive dredging often costs more and delivers less predictable results. Planned dredging and pumping programs enable facilities to operate under favourable conditions rather than being forced into emergency response.

Using proven Canadian dredging solutions supports safer operations by reducing manual handling, limiting equipment stress, and enabling efficient work completion. For operators, this translates into fewer urgent callouts, clearer maintenance schedules, and more confidence that systems will perform as required.

A Simple Checklist for Effective Dredging and Pumping Planning

Successful dredging and pumping work starts with clear planning. When the basics are addressed early, projects run more smoothly and place less pressure on operating teams.

Material assessment

Understanding what needs to be removed is critical. Sludge thickness, solids concentration, and the presence of sand or debris all affect equipment selection. Accurate assessment reduces the risk of underperforming pumps and unexpected downtime.

Flow and discharge requirements

Facilities must know how much material needs to be moved and where it will go. Flow rates, discharge distance, and elevation changes directly influence pump sizing. In Canada water treatment dredging, matching the pump to the application is one of the most important decisions.

Access and power availability

Many Canadian sites have limited access and short setup windows. Space, power supply, and safety requirements should be considered early. Choosing the right pumping configuration helps crews work efficiently without disrupting surrounding operations.

Maintenance and inspection planning

High-solids pumping creates wear. Planning for inspections and replacement parts prevents small issues from becoming major failures. This supports consistent wastewater management and reduces stress on maintenance teams.

Seasonal timing and staffing

Work should be planned around weather conditions and available labour. Scheduled dredging during favourable periods is safer, more efficient, and easier to manage than emergency work during extreme conditions.

Following a clear checklist turns Canada water treatment dredging into a controlled process rather than a reactive response. When paired with reliable Canadian dredging solutions, facilities gain predictability and confidence in how solids are managed.

Building More Resilient Water and Wastewater Systems in Canada

Water and wastewater systems are expected to perform every day, often under difficult conditions. When solids are allowed to accumulate, that expectation becomes harder to meet. Capacity is lost, equipment is strained, and operators are forced to address problems rather than prevent them.

Addressing solids through Canada water treatment dredging is one of the most practical ways to strengthen long-term system performance. When sediment and sludge are removed regularly, facilities regain capacity, stabilize flow, and reduce the operational pressure placed on staff and equipment. This directly supports more reliable wastewater management across municipal and industrial sites.

The right pumping and dredging approach turns solids control into a routine maintenance activity rather than an emergency response. With proven Canadian dredging solutions, operators can plan work around seasonal constraints, manage risk more effectively, and extend the life of existing infrastructure.

Pump and Dredge Direct supports this approach by helping Canadian facilities select dependable pumping and dredging equipment suited to real operating conditions. By focusing on practical solutions and long-term reliability, solids management becomes easier to control and less disruptive to daily operations.

In a system with little margin for error, proactive solids management provides what every operator values: confidence that the system will perform when it is needed most.