Pumps are the backbone of countless industries, playing a vital role in moving liquids, slurries, and gases efficiently through complex systems. From water treatment facilities and chemical plants to mining operations and oil refineries, reliable pumping solutions are essential for day-to-day operations and long-term sustainability. As global industries continue to demand higher efficiency, reliability, and adaptability, the role of pump manufacturers becomes increasingly critical.

At the forefront of this transformation are industrial pump manufacturers, who are not just producing equipment but also engineering comprehensive solutions that drive performance improvements across sectors. These manufacturers are investing heavily in research, development, and technology integration to meet the unique challenges of each industry, from extreme temperatures and corrosive materials to energy consumption and system compatibility.

In particular, hydraulic pump manufacturers are spearheading advancements in heavy-duty applications, where precision control and high-power density are key. Their innovations are reshaping how industries approach automation, mobility, and sustainability. Meanwhile, industrial pump manufacturers are also focused on creating smarter, greener, and more durable pumping systems that align with modern operational goals.

As this blog will explore, pump makers are not just keeping pace with industry evolution—they’re helping lead it, setting the standards for the next generation of industrial pumping solutions.

The Evolving Role of Pump Manufacturers

In today’s rapidly advancing industrial landscape, the role of pump makers has significantly evolved. No longer seen merely as suppliers of hardware, they are now recognized as strategic partners offering end-to-end solutions. This shift is being driven by growing operational complexity, increased performance expectations, and the need for more intelligent and energy-efficient systems. Across industries, there is a clear demand for integrated pumping solutions that go beyond standard equipment to deliver reliability, automation, and long-term value.

Industrial pump manufacturers are responding by offering more than just off-the-shelf products—they are developing fully engineered systems tailored to specific operational needs. Whether it’s in wastewater treatment, power generation, or food processing, these manufacturers are designing pump systems that integrate seamlessly with control panels, sensors, variable frequency drives, and remote monitoring capabilities. This holistic approach enables better system performance, predictive maintenance, and reduced downtime.

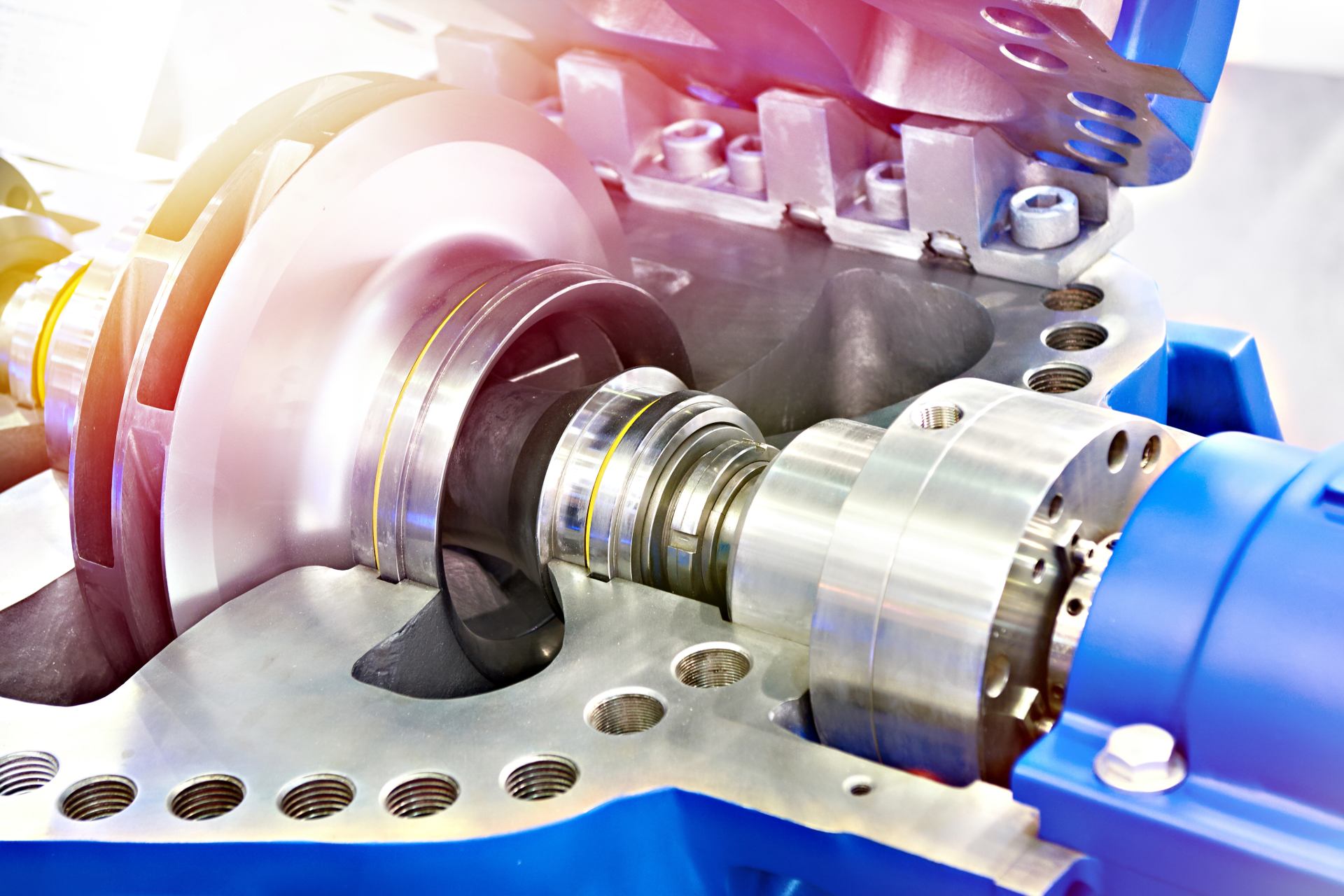

Hydraulic pump manufacturers, in particular, have stepped up to meet the demands of industries that require high power in compact footprints. From mobile construction equipment to offshore drilling platforms, these manufacturers are providing rugged, precision-engineered hydraulic systems that are built for tough environments and dynamic load requirements. The integration of electronics with hydraulic control systems is allowing for enhanced accuracy, safety, and responsiveness.

Additionally, the industry has seen a strong shift toward customization and service-based models. Both industrial pump manufacturers and hydraulic pump manufacturers are increasingly offering personalized solutions based on specific fluid properties, operating conditions, and process goals. This includes designing pump curves for unique applications, adapting materials for chemical resistance, and offering modular designs that allow for easy upgrades.

Service has become a core part of the offering as well. Many manufacturers now provide ongoing support through lifecycle management, performance audits, and training programs. These value-added services ensure that clients receive not just a product, but a long-term performance partner.

This transformation underscores the growing importance of manufacturers who not only understand the mechanics of pumping but also the broader systems and challenges their clients face. Their ability to deliver smart, adaptable, and integrated pumping solutions is what sets them apart in the modern industrial era.

Innovation Trends Among Industrial Pump Manufacturers

As industries demand greater efficiency, reliability, and sustainability, pump makers are stepping up with a new wave of innovations. Industrial pump manufacturers are at the forefront of this transformation, leading the charge in research and development to create high-performance systems that meet evolving operational requirements across sectors such as mining, oil and gas, power generation, and water management.

One of the key areas where industrial pump manufacturers are making strides is in material science. The adoption of advanced materials such as corrosion-resistant alloys, ceramics, and composite polymers is significantly enhancing pump lifespan and reducing maintenance costs. These materials offer superior resistance to chemical degradation, abrasion, and high temperatures, making them ideal for harsh industrial environments.

In parallel, hydraulic pump manufacturers are engineering cutting-edge systems designed for maximum efficiency and reliability in high-pressure applications. They are developing pumps with tighter tolerances, better sealing mechanisms, and energy-saving features such as variable displacement controls. These improvements allow for precise fluid delivery, reduced energy consumption, and extended equipment life, especially important in industries where downtime can be extremely costly.

Design innovation is another area where both industrial pump manufacturers and hydraulic pump manufacturers are making significant progress. New pump geometries, impeller designs, and flow path optimizations are resulting in improved flow control, more stable pressure management, and reduced cavitation risk. Additionally, computational fluid dynamics (CFD) simulations and rapid prototyping techniques are accelerating the development cycle and allowing manufacturers to fine-tune designs before physical testing.

Intelligent pump systems are also emerging as a standard. With the integration of smart sensors and real-time data monitoring, manufacturers are transforming traditional pumps into intelligent machines capable of self-diagnosis, performance optimization, and predictive maintenance. This smart technology enables industrial users to anticipate failures, optimize energy use, and maintain consistent operational output.

The combined impact of these innovation trends is profound. Industrial pump manufacturers are not only enhancing equipment durability and efficiency but are also paving the way for digital transformation in fluid management. Likewise, hydraulic pump manufacturers are pushing the limits of performance and precision, shaping the future of motion control in heavy-duty industries. These advancements are redefining what’s possible in industrial pumping systems.

Hydraulic Pump Manufacturers and the Push for Efficiency

In an era where energy efficiency and operational cost reduction are top priorities, hydraulic pump manufacturers are taking bold steps to redefine performance in heavy-duty applications. From construction and mining to marine and offshore operations, these manufacturers are introducing cutting-edge technologies that deliver high power output with lower energy input, making hydraulic systems more efficient and sustainable than ever before.

A breakthrough has been the widespread adoption of variable displacement pumps. Unlike traditional fixed displacement designs, these pumps adjust flow and pressure in real-time based on system demand. This not only reduces energy consumption but also minimizes heat generation and extends the life of system components. Hydraulic pump manufacturers are engineering these pumps with advanced control mechanisms, enabling smoother operation and greater flexibility across a range of industrial applications.

Noise reduction is another area of significant innovation. Modern hydraulic systems are being designed with quieter components, improved dampening, and optimized flow paths to reduce acoustic impact. This is especially critical in urban construction projects and marine environments where noise pollution can be a concern. These advancements enhance operator comfort while also meeting stricter noise regulations.

While hydraulic systems are gaining efficiency, they must still meet the performance demands of the industries they serve. Hydraulic pump manufacturers are achieving this balance through rugged construction, precision engineering, and the integration of digital control technologies. These improvements ensure reliable performance in extreme environments, whether powering an excavator in a remote mine or supporting deck operations on a maritime vessel.

At the same time, industrial pump manufacturers are taking cues from their hydraulic counterparts by integrating similar energy-efficient principles into broader pumping applications. The convergence of design strategies across disciplines is creating more cohesive and optimized systems.

As the demand for energy-efficient, high-performance solutions continues to rise, both hydraulic pump manufacturers and industrial pump manufacturers are proving essential to progress. Their innovations are enabling industries to do more with less, driving productivity while reducing environmental impact.

Smart Pumps: Integrating IoT and Automation

The rise of the Internet of Things (IoT) is revolutionizing how industrial systems operate, and the pumping sector is no exception. Smart pumps—pumping systems embedded with sensors, control units, and communication technology—are transforming traditional maintenance-intensive operations into fully automated, insight-driven ecosystems. These advancements are helping facilities reduce downtime, optimize energy use, and achieve higher levels of operational reliability.

One of the key benefits of smart pumps is their ability to support predictive maintenance. Rather than relying on routine checkups or reacting to breakdowns, smart pumps continuously monitor parameters such as flow rate, temperature, vibration, and pressure. These data points are analyzed in real-time to detect anomalies that indicate wear, cavitation, or impending failure. Maintenance teams receive alerts before issues escalate, allowing for timely interventions and avoiding costly unplanned shutdowns.

Remote monitoring capabilities take this a step further by enabling operators to oversee pump performance from any location. Through cloud-based dashboards, plant managers can visualize trends, track energy usage, and receive automated reports. These platforms also allow for remote diagnostics, reducing the need for on-site visits and accelerating troubleshooting when problems arise. This level of accessibility and transparency supports faster decision-making and better resource allocation.

Smart pumps are making a significant impact across multiple industries. In water treatment plants, they ensure optimal flow and pressure in distribution systems while minimizing energy use. In oil and gas operations, smart pumps help manage corrosive and high-viscosity fluids with precision and reliability. Manufacturing plants are using them to maintain consistent product quality by automating flow control in chemical and material processing.

Additionally, smart pump systems can be integrated into building management systems (BMS) and SCADA platforms, creating unified control over infrastructure. This integration streamlines facility operations and allows for coordinated responses to changing conditions or demand surges.

As industrial facilities strive for smarter, more efficient operations, the adoption of IoT-enabled pump technology is no longer a luxury—it’s a strategic advantage. Smart pumps are paving the way for a new era of connected, intelligent, and responsive industrial infrastructure.

Sustainable Manufacturing and Eco-Friendly Designs

As environmental regulations tighten and global industries shift toward greener operations, pump makers are prioritizing sustainability in both design and production. Reducing carbon footprints, minimizing waste, and improving energy efficiency have become core objectives as manufacturers respond to customer demands and environmental responsibilities.

One of the most impactful strategies has been the integration of sustainable manufacturing practices. Pump makers are reconfiguring their production processes to use less energy and water while also reducing emissions. Many are transitioning to renewable energy sources at their manufacturing facilities and implementing closed-loop systems to recycle water and waste materials. These changes not only lower environmental impact but also improve overall operational efficiency.

The shift toward eco-conscious product design is also shaping the future of pumping technology. Manufacturers are developing pumps that support green infrastructure projects, such as stormwater management systems, wastewater recycling plants, and renewable energy installations. These pumps are optimized for low energy consumption, high efficiency, and minimal maintenance, aligning with the long-term goals of sustainable development.

In addition, the use of recyclable and environmentally friendly materials is becoming more common. Components made from recycled metals, biodegradable polymers, and low-toxicity coatings are helping extend product lifecycles while reducing environmental harm. Some manufacturers are also designing modular pump systems that allow for easier upgrades and repairs, further reducing waste and resource consumption.

Low-emission techniques are being applied across the value chain, from casting and machining to assembly and shipping. Packaging is also being redesigned to minimize plastic use and promote recyclable alternatives.

By adopting these sustainable innovations, pump manufacturers are not only complying with environmental standards but also playing an active role in advancing eco-friendly industrial practices. Their efforts are contributing to a cleaner, more responsible future, where high-performance pumping systems coexist with sustainable environmental stewardship.

Conclusion

Leading pump makers are playing a pivotal role in shaping the future of industrial operations. Through relentless innovation, they’ve transformed basic pumping systems into intelligent, energy-efficient solutions that drive performance, reduce downtime, and support complex applications across industries. From advanced materials and smart automation to sustainable manufacturing practices, these manufacturers continue to push the boundaries of what pumping systems can achieve.

Hydraulic pump manufacturers, in particular, are driving major advancements in high-power applications, offering compact, efficient, and digitally enhanced solutions for demanding industries like construction and marine. Their contributions are key to the evolution of motion control and energy efficiency.

As industries evolve, the demand for high-efficiency, digitally connected, and environmentally responsible solutions will only grow. Staying aligned with forward-thinking pump suppliers and hydraulic pump manufacturers ensures that businesses remain competitive, resilient, and prepared for the future.